Warehousing and Distribution

Article | July 11, 2023

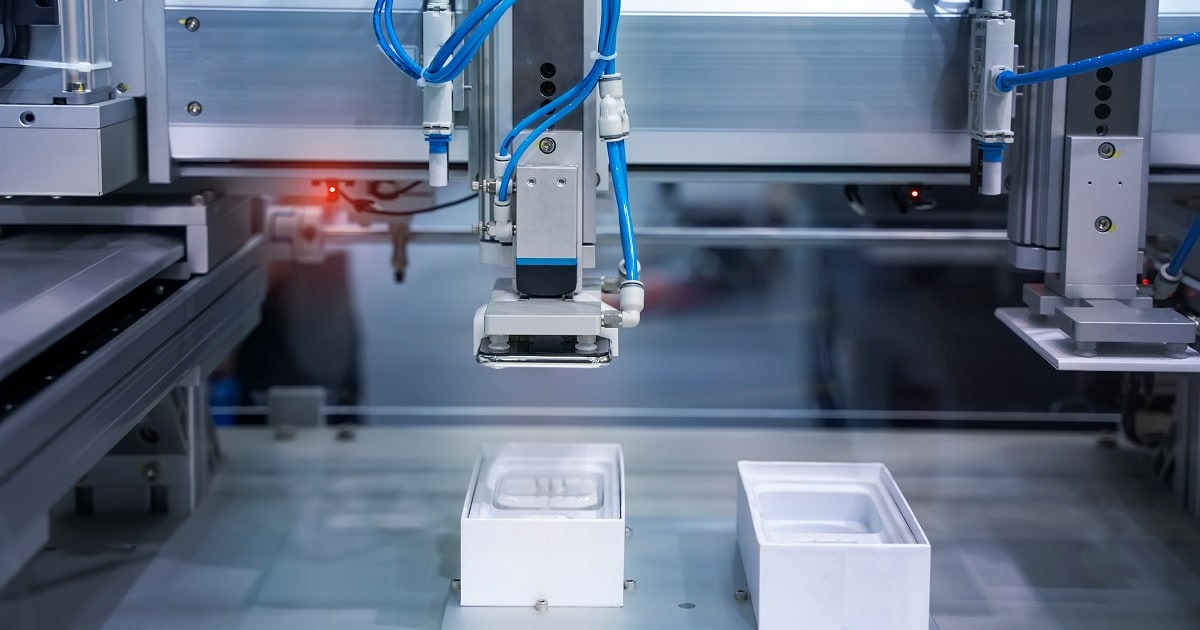

Autonomous robots have transitioned from a futuristic system that only a few enterprises could afford to a sustainable, well-established solution in a wide assortment of warehouse automation projects in recent years.

With the flourishing transportation and logistics industry and increasing e-commerce penetration worldwide, innovative technologies are revealing promising opportunities throughout the supply chain.

Warehouse Automation: Driving Value in the Supply Chain

Historically, autonomous robots have been used to perform tedious and repetitive tasks, necessitating sophisticated programming for setup and incorporation while lacking the dexterity to easily adjust operations.

As autonomous robots become more intelligent, their setup times decrease, they need less monitoring, and they are able to work alongside their human counterparts. The benefits for the future supply chain are increasing as autonomous robots become more capable of working day and night with more consistent levels of productivity and quality and performing tasks that individuals should not, cannot, or do not want to do.

Autonomous robots drive advancements and add value to the supply chain, primarily by increasing revenue potential and lowering direct and indirect operating costs. Autonomous robots, in particular, can assist:

Boost efficiency and productivity.

Lower risk, error frequency, and rework rates.

Enhance employee safety in high-risk workplaces.

Handle low-value, routine tasks so people can work together on strategic projects that can't be done by machines.

Raise revenue by optimizing order fulfillment rates, and delivery speed, and, ultimately, increasing customer satisfaction.

Sneak Peek into the Future of Autonomous Robot

Autonomous robots are expected to witness strong growth in the coming years. These robots will become more common in the future supply chain as technology advances, allowing them to operate with more human-like abilities. Improvements in haptic sensors, for example, will enable these robots to grasp objects varying from multi-surfaced metal assembly parts to fragile eggshells without requiring changes to robotic components or programming. This will encourage companies operating in the industry to increase their research and development activities and introduce innovative and advanced supply chain technologies.

Read More

Supply Chain

Article | May 22, 2023

The unsurprising investment eagerness of venture capital funds is manifesting in an automation tech glut in the distribution center space. Motivated by enabling trends like labor and land shortages, DCs are amid an automation transformation. Never has defining an automation strategy been more important.

There’s no shortage of VC cash available to logistics tech startups

With a brightly shining spotlight centered on supply chains for the past two years, it’s no surprise that total funding in logistics startups has seen a dramatic increase – growing at over 70% CAGR (Compound Annual Growth Rate). Logistics technology startups raked in over $25 billion in the first three quarters of 2021. That’s more than half of the total amount raised in the whole of 2020, and the incentives for continuing investment persist.

The rise of the of the “micro” DC

“Micro” is a relative term. The size of a micro fulfillment center (MFC) can range from 5,000 to 50,000 square feet. Those reduced square footages allow location in dense urban areas, typically within 40 miles of most of their intended customers. In addition, smaller footprints lead to reduced rents compared to a standard customer fulfillment center (CFC), and the proximity to consumers makes for lower final mile delivery costs. It’s no wonder that MFCs accounted for more than half of the logistics real estate leasing activity in the third quarter of 2021. The “urban logistics” trend is fueling demand for these highly automated, smaller locations.

Vertical logistics integration grows ever more fashionable among retailers

It’s a very “in” thing right now, these acquisitions and partnerships, and they won’t be going out of fashion soon. For example, American Eagle took in Airterra and its parcel optimization tech and third-party logistics (3PL) provider Quiet Logistics.

Target started early. They bought Grand Junction, a software platform that helps retailers determine the best delivery method and track carrier performance, in 2017. Their 2020 acquisition of Deliv brought with it same-day delivery routing technology that they’re now applying to their 2021 purchase, on-demand delivery service Shipt. Target uses Delivs’ tech to generate more efficient routes for Shipt.

Kroger has partnered with UK’s e-grocery specialist Ocado to build automated CFCs across the US and expand their retail footprint. The first CFC opened last spring in Ohio and their second in Florida later that year. They plan to open 20 CFCs over the next three years.

“The proliferation of DC automation solutions and modalities, the rise of MFCs in high-density urban areas, the increasingly automated vertical integration of logistics, and the need to rapidly expand order fulfillment capacity have all, in combination, advanced the need for and application of clearly defined strategies concerning the implementation of automation technology. Do not operate without one.”

Vikas Argod, Principal, Supply Chains Operations practice at Chainalytics

Coping with shortages in warehouse space and labor availability

Third quarter, 2021 US demand for industrial real estate exceeded supply by 41 million square feet. This pushed the national vacancy rate in the fourth quarter down to a record 3.7% in the Cushman & Wakefield US National Industrial MarketBeat report for Q4 2021. Who knows what the record might be when the Q1 2022 report breaks in a few weeks?

On the labor side, the December 2021 US unemployment rate was 3.9%, lower than in December 2019 (3.6%) yet reflecting a tighter labor market. Labor force participation rates are at 61.9%, nearly 2% below February 2020 levels, because of lingering effects of the COVID-19 pandemic. The rising wages and signing bonuses of the past year offer silent testimony to the ongoing constraints in today’s labor market.

Both trends will remain with us for the near- and mid-term, making an automation strategy a necessary part of your DC operations as you attempt to mitigate the effects of both. In addition, warehouse labor shortages are most pronounced in markets with high distribution center densities – Greater Memphis, In-land Empire, Allentown, PA, et al.)

Building the capability to rapidly open DCs at scale

No other factor drives home the need for a coherent DC automation strategy like this one. Let’s explore it with an example.

We’ll call this “A Tale of Two Companies.” One jumped on the automation bandwagon without hesitation – not a bad thing – but applied no strategic groundwork. The other is, well, Amazon.

Company one responded to increasing demand by creating DCs in their usual, strategically located fashion. However, with automation, the lack of a logical strategy led to adopting “the best that money could buy.” So, while these DCs work fine on their own (most of the time), each employs unique implementations from a variety of vendors, with little to no overlap of methods, capabilities, and management procedures between DCs. It’s functional, but a needlessly complicated hodgepodge.

On the other hand, it definitely looks like Amazon has a standardized automation strategy. One that can easily adapt to exploit the individual physical specifications of any space. This makes it simple to arrive and equip it with a standard package of automation solutions. That’s probably how Amazon blanketed the US with over 400 new DCs in just the last two years. They waste no time or money on repeating unnecessary decisions along the way.

Now, we all can’t have the resources of an Amazon. However, the rise of on-demand warehousing companies like Stord and Flexe allow organizations to dramatically decrease the cycle time of standing up additional fulfillment capability.

Developing an automation strategy will feel familiar. It begins with benchmarking, order profiling, current performance drivers, EBIT targets, and theoretical evaluations of newer technology options. All this leads to the creation of a decision framework for DC automation. The goal here is achieving alignment among the leadership on critical capabilities to focus on. These include rapid fulfillment, labor shortage, capacity constraints, safety challenges, or sustainability. Those that commit to this process will start slowly but finish with a strategy that will underpin thousands of decisions and enable sustained rapid growth.

If, in the end, you decide that automation is not right for your operation, that’s a perfectly valid strategy as well. So long as you have a method to evaluate all of your options, and you base your decision on cost-service-sustainability trade-offs, the right strategy for your organization may be no automation at all.

There’s no point in chasing shiny robotic objects if automation makes little sense.

The rise of automation and the multitude of technologies to choose from require the development of a strategic decision framework. Contact us and see how Chainalytics – an NTT DATA company – can be your guide in developing this critical part of your foundation for growth. Our top supply chain talent, enabled by proven, leading-edge digital assets – tools, methods, and content – deliver actionable insights and measurable outcomes to some of today’s largest and most complex supply chains.

Read More

Warehousing and Distribution

Article | July 17, 2023

Data volume in supply chains is usually enormous. Analytics applied to the supply chain help make sense of the pile of information by identifying patterns and drawing conclusions.

Contents

1 Importance of B2B Supply Chain Analytics

2 Obstacles in Supply Chain Analytics Integration

2.1 Barriers in Collecting and Processing Data

2.2 Insufficient Technical Skills

2.3 Issues in Managing and Integrating Data

2.4 Inadequate Analytics and Insights Generation

3 Addressing Supply Chain Analytics Complexities for Better Decision-Making

3.1 Leveraging External Expertise

3.2 Enhancing Collaboration and Communication

3.3 Improving Data Quality and Governance

3.4 Developing Analytics Capabilities

4 Power of Successful Supply Chain Analytics Integration in Transforming Businesses

5 Conclusion

1 Importance of B2B Supply Chain Analytics

Supply chain analytics has become a pillar of contemporary business strategy, enabling organizations to leverage data insights and enhance vital supply chain processes. By utilizing real-time data analytics, businesses can streamline their supply chain operations, boost productivity, and increase customer satisfaction. With unparalleled visibility into key performance indicators, B2B supply chain analytics provide the opportunity to identify inefficiencies, reduce costs, and react swiftly to ever-changing market dynamics, streamlining the process for supply chain business analysts who manage supply data.

Leveraging the power of supply chain analytics tools is important for the success of modern businesses in the age of data-driven decision making. With the ability to optimize inventory levels, manage lead times, and reduce transportation costs, supply chain data analytics provides a competitive advantage that can increase the efficiency, productivity, and profitability of businesses of all sizes and in all industries.

2 Obstacles in Supply Chain Analytics Integration

Supply chain analytics integration has become increasingly critical for companies seeking to optimize their supply chain operations. However, several obstacles hindering successful implementation often complicate the integration process; hence, understanding and knowing them in advance is vital for smooth operations.

2.1 Barriers in Collecting and Processing Data

Effective data collection and processing are critical in generating accurate insights to drive supply chain analytics decision-making. However, it comes with challenges; the most critical obstacle is data silos, where data is stored in isolated systems or departments, leading to difficulties in accessing and integrating it. It gets more complex when different departments or partners use varied data formats or standards. Additionally, cleaning and processing data is also challenging, as it involves identifying and eliminating duplicates, inconsistencies, and errors that can negatively impact analytics accuracy.

2.2 Insufficient Technical Skills

Successful supply chain analytics integration depends heavily on technical skills and knowledge. Insufficient technical talent and expertise are significant barriers to successful integration. The integration process requires specialized technical expertise and the supply of skilled professionals with expertise in ETL, statistical analysis, knowledge of ML, IoT, SQL, and more in managing supply chain analytics Talent lacking technical skills cannot accurately interpret data, leading to ineffective

decision-making. Preliminary data analysis, processing, and visualization due to a lack of technical expertise results in suboptimal decision-making, which can be costly for businesses.

2.3 Issues in Managing and Integrating Data

Data integration combines data from various sources and formats to create a unified view. However, businesses face data governance, quality, and standardization issues, resulting in incomplete or inconsistent data. Lack of accurate information reduces the efficiency of supply chain analytics and impacts decision-making. Additionally, data management is complex, and business face difficulties creating effective data management processes, resulting in problems related to storing, retrieving, and updating data.

2.4 Inadequate Analytics and Insights Generation

Obtaining valuable insights from enormous data collected during the supply chain process requires advanced analytics tools and technologies. Many businesses, however, continue to rely on traditional reporting methods, which limit the range and complexity of insights generated. The lack of expertise in data analysis and visualization can lead to poor interpretation and use of data, resulting in suboptimal decision-making. In addition, businesses experience difficulty identifying relevant data sources or may struggle to establish the necessary data governance frameworks to ensure data quality and accuracy.

3 Addressing Supply Chain Analytics Complexities for Better Decision-Making

Supply chain analytics can provide valuable insights, but the complexities involved in analyzing and interpreting data can be a significant hurdle. Learning the strategies for addressing these complexities to improve decision-making in supply chain management has become essential.

3.1 Leveraging External Expertise

Leveraging external expertise can be a powerful strategy for addressing supply chain analytics complexities related to collecting and processing supply chain data during integration. External experts bring specialized skills, experience, and knowledge that may not be available in-house, enabling organizations to overcome talent shortages and expand their capabilities. Furthermore, consultants, data scientists, or technology providers provide an objective viewpoint on the organization's data and processes, identifying areas for improvement and optimizing performance. By collaborating with external experts, organizations can access the latest tools, technologies, and best practices, ensuring that their supply chain analytics are up-to-date and relevant.

3.2 Enhancing Collaboration and Communication

Enhancing collaboration and communication can effectively address the challenge of insufficient technical skills in thriving supply chain analytics integration. By promoting cooperation and cross-functional communication, organizations can leverage the skills and expertise of team members from various departments to fill gaps in technical knowledge. This approach can also help to break down data silos and improve data sharing and integration. In addition, collaboration and communication can facilitate knowledge transfer, enabling team members to learn from one another and develop a more comprehensive understanding of the supply chain analytics process. Ultimately, this can lead to improved decision-making, as a more skilled and knowledgeable team can generate more accurate and insightful analytics.

3.3 Improving Data Quality and Governance

Businesses ensure accuracy, completion, and up-to-date data by establishing standardized processes and protocols for collecting, storing, and analyzing data. Data quality checks, including data cleansing and normalization, can help eliminate errors, redundancies, and inconsistencies that can negatively impact the accuracy and usefulness of analytics. In addition, effective data governance, including establishing data ownership, security, and privacy policies, helps ensure that data is managed and shared appropriately across the organization. As a result, it reduces the risk of data breaches, compliance violations, and other data-related issues, ensuring that organizations have access to reliable data for better decision-making.

3.4 Developing Analytics Capabilities

Developing capabilities significantly help organizations overcome inadequate analytics and insights generation challenges in analytics integration. Investing in advanced analytics tools and platforms like technical skills, data infrastructure, and advanced supply chain analytics techniques help businesses generate real-time, accurate, and actionable insights from collected data. Developing analytics capabilities requires creating a culture that values data and analytics, establishing robust data governance frameworks, upskilling the workforce and creating cross-functional teams collaborating on data-related projects. In addition, it helps businesses gain a competitive advantage.

4 Power of Successful Supply Chain Analytics Integration in Transforming Businesses

Effective supply chain analytics integration is revolutionizing business operations. Real-time and supply chain predictive analytics have helped businesses gain unmatched transparency in their supply chains, enhance critical processes, improve operational efficiency and customer satisfaction, and experience revenue growth and profitability. The ability to identify inefficiencies and supply chain optimization opportunities enables businesses to effectively allocate resources and reduce expenses. In addition, successful supply chain analytics integration enables businesses to respond quickly to changing market dynamics, optimize inventory management, and strengthen the resilience of their supply chains.

Businesses are leveraging the power of big data analytics to disrupt and transform supply chain at all levels. The concept of data, which was once a fundamental component of digital supply chain transformation, is now revolutionary. Therefore, it is essential to achieve advancements in supply chain analytics integration and management.

5 Conclusion

With technological and data analytics advancements, businesses can utilize real-time data insights to make data-driven decisions, optimize supply chain processes, and improve customer experiences. Integration of supply chain analytics is crucial for supply chain businesses of all sizes. Utilizing supply chain analytics software can further streamline integration as well as enhance data analytics and supply chain management.

Read More

Article | April 20, 2021

You might be wondering what the benefits are of benchmarking. Well, imagine you are training for a 100 metre sprint in your district. What would be the key number, or metric that you would need to know?

It would, of course, be what the winning time was when this race was last run in your district. Without that information, you don’t know what you’re trying to target. It would be impossible to know if you’ll have any chance at all of winning the race.

It’s exactly the same in business. If, for example, you are concerned about the pick rates in your warehouse, or your transport costs, or your inventory accuracy, benchmarking can help you because it can show you exactly where your performance is compared to others in your industry.

A few years ago, I was working with an automotive parts business. They had a little issue with their picking productivity in the warehouse. They wondered how good it was, whether they could improve it. They actually thought it was okay.

We looked at the figures and compared them with other businesses. This helped us realise that their picking productivity should be three times better than it was. And believe it or not, over a few months they did begin to improve their productivity.

Why? Because benchmarking opened their eyes to the fact that they were at a level quite far below others in the industry.

That’s the beauty of benchmarking. Until you know what others are doing, you can’t be sure how good your performance is.

If you’ve never tried benchmarking, there are three ways you could do it.

1. Informal Benchmarking

This exercise would involve you measuring particular functions or aspects of your business and comparing that against other parts of your business. Let’s say you have a warehouse operating in one city and another operating in another city. You might start to measure the same metrics and see which one is performing better.

You might know other people in the industry who are also operating warehouses so you might agree to share some data with them.

This is probably the easiest way to start off, but it has some downsides:

You’re only measuring against a very small sample size. If all of you in the pool are not that good, how would you know what good is?

You have to make sure that the businesses are similar and you are measuring things in exactly the same way. It’s very important in benchmarking to have a standard way of applying the metric.

2. Formal Benchmarking

This can work for much larger businesses. Perhaps you have operations in many different countries. You could agree a formal structure for how you are going to measure performance. You could do monthly or quarterly benchmarks with all the parts of your international organisation. You could learn from each other and share best practice.

This method is okay but you’re not getting access to a very large pool of results to measure yourself against. You will find that companies are very reluctant to give out benchmarking data. You might also be operating in an environment where the performance is quite low right across the business.

3. Hire a Professional Benchmarking Firm

This is the ultimate way to do it, although there are not a lot of professional benchmarking firms such as ours around. If you do manage to find one, you will quickly realise that there are significant benefits to be had by bringing in the professionals:

The metrics are put together in exactly the same way: When we do a benchmarking exercise for our consulting clients, we go through a very robust data-gathering process and then make sure all the costs, for example, are in the same buckets as everyone else’s in the database.

You gain access to a big pool of results: Professionals have measured hundreds, if not thousands, of companies. This enables you to say, ‘Our company is this size, it operates in this industry, these are the characteristics of our supply chain, who else in that pool of results is like us? We want to be measured against them.”

It’s no good measuring the performance of a grocery retailer, for example, against an industrial product supplier. They have different supply chains. You need to be measuring like with like.

Read More