Supply Chain

Article | May 22, 2023

Efficient demand forecasting techniques transform supply chain management, help optimize inventory levels, streamline operations, improve customer satisfaction, and achieve a competitive edge.

Contents

1. How Accurate Demand Forecasting Impacts Business Operations and Profitability?

2. Navigating the Pitfalls of Traditional Demand Forecasting

2.1 Limitations of Manual Forecasting Methods

2.2 Inaccuracy and Inconsistency in Demand Prediction

2.3 Multiple Products and Markets Challenges

2.4 Influence of External Factors on Demand Forecasting

3. Advanced Demand Forecasting Techniques for Supply Chain Management

3.1 Statistical Forecasting

3.2 Collaborative Demand Planning

3.3 Demand Sensing and Real-time Data Analytics

3.4 Agile Supply Chain Management Practices

4 Summing up

1. How Accurate Demand Forecasting Impacts Business Operations and Profitability?

Accurate demand forecasting plays a vital role in determining the operations and profitability of a business. By anticipating future demand, companies can more effectively plan their production, inventory management, and supply chain activities to meet customer needs while minimizing costs.

Additionally, accurate demand forecasting can aid businesses in enhancing customer satisfaction by proactively meeting customer needs and expectations, improving customer experiences and increasing customer loyalty. To generate actionable insights that drive informed decision-making, businesses must leverage advanced analytics and predictive modeling techniques that combine data from various sources with industry-specific knowledge and expertise.

“Businesses that leverage advanced analytics and predictive modeling techniques for demand forecasting report an average of 5% improvement in their supply chain efficiency.”

(Source: A survey by Deloitte)

Supply chain businesses frequently rely on sales data from the past, which may not be sufficient in the complex and rapidly changing business environment. Businesses might not observe an improvement in operations and profitability if they rely solely on conventional methods.

2. Navigating the Pitfalls of Traditional Demand Forecasting

As businesses strive to optimize their supply chain operations and meet customer demand, traditional demand forecasting methods can often hinder their efforts. In this context, it is essential to navigate the pitfalls of such techniques to achieve success in supply chain management.

2.1 Limitations of Manual Forecasting Methods

Manual forecasting methods have limitations that can affect demand forecasting accuracy in supply chain management. Frequently based on historical data, these methods can overlook emerging trends in supply chain management and alterations in customer behavior. In addition, manual processes are time-consuming, prone to error, and incapable of incorporating real-time supply chain data. As a result, businesses struggle to optimize supply chain operations and meet customer demand.

In addition, traditional forecasting methods can influence the ability to accurately predict demand, resulting in overstocked inventory, delivery delays, and, ultimately, poor customer satisfaction. Inaccurate demand forecasts can also result in poor purchasing decisions and increased carrying costs, negatively impacting profitability.

2.2 Inaccuracy and Inconsistency in Demand Prediction

Inaccuracy and inconsistency in demand forecasting pose significant obstacles in managing the supply chain. This is the case in the dynamic business environment, where market conditions can change rapidly, making it challenging for companies to keep up with shifting demand patterns. As traditional demand forecasting methods depend heavily on historical data, they produce inaccurate forecasts that do not reflect real-time market changes.

In addition, inconsistency in demand forecasting can also result in a mismatch between supply and demand, leading to missed opportunities or excess inventory. As a result, creating an effect on company’s bottom line in addition to customer satisfaction.

2.3 Multiple Products and Markets Challenges

Accurate demand forecasting is crucial to the success of supply chain management. When there are multiple products and markets to manage, it becomes a challenge for traditional demand forecasting. Different products and markets may have varying demand patterns and drivers, making it difficult for businesses to accurately forecast demand.

Manual processes and siloed data can hinder visibility and the ability to identify cross-product or cross-market trends, making supply chain optimization operations and meeting customer demand more complex. Managing multiple products and markets is one of the challenges of traditional demand forecasting when businesses operate in various markets with varying customer preferences and demand patterns for products.

2.4 Influence of External Factors on Demand Forecasting

External factors can significantly impact the demand forecasting accuracy for supply chain optimization. These factors are often unpredictable, and conventional methods may not account for them. The external factors affecting the supply chain include natural disasters, economic recessions, and sudden changes in consumer behavior.

In addition, political and regulatory modifications, such as tariffs or trade agreements, can affect the supply and demand of particular products. Therefore, businesses must incorporate these external factors into their demand forecasting models and advance the process, as traditional demand forecasting methods cannot predict accurate future demand patterns and ensure optimal supply chain operations.

3. Advanced Demand Forecasting Techniques for Supply Chain Management

To avoid the above-mentioned pitfalls, companies need to adopt advanced demand forecasting techniques that enable capturing and analyzing huge data from various sources to generate accurate and real-time demand forecasts.

3.1 Statistical Forecasting

Statistical forecasting is an advanced method for demand forecasting in supply chain management that utilizes complex algorithms and statistical models to analyze historical data, identify trends, and generate forecasts. This method employs numerous statistical techniques, including regression analysis, time-series analysis, and exponential smoothing, among others.

Statistical forecasting can help businesses overcome some of the limitations of traditional manual forecasting methods because it is more objective, data-driven, and capable of identifying trends and patterns which are not apparent with manual forecasting methods. As a result, by utilizing statistical forecasting, businesses can increase demand forecasting accuracy, optimize inventory management, and better align supply and demand, resulting in enhanced customer satisfaction, greater efficiency, and lower costs.

3.2 Collaborative Demand Planning

Collaborative Demand Planning combines intensive forecasting algorithms to predict future demand and a set of ML techniques to achieve better demand forecasting. It involves collaboration between suppliers, customers, and other stakeholders. The advanced data and insights sharing technique improve the comprehensive understanding of demand drivers and trends, leading to more accurate demand forecasting. The collaborative approach enables real-time adjustments to demand forecasts, which can help businesses respond promptly to market conditions and customer demand changes.

In addition, using advanced analytics and machine learning algorithms can help identify patterns and trends that would otherwise go unnoticed. That enables businesses to optimize inventory levels, reduce under and overstocking, and enhance customer service levels. In the dynamic business environment, it helps transform the supply chain that is better equipped to meet the ever-changing demands of customers.

3.3 Demand Sensing and Real-time Data Analytics

Demand Sensing and Real-time Data Analytics are advanced demand forecasting techniques that can assist businesses in overcoming the challenges that multiple products and markets pose to the supply chain. By utilizing real-time data from various sources, such as social media, point-of-sale systems, and weather reports, businesses can better understand customer demand patterns, adjust inventory and production planning, reduce delay, and increase responsiveness.

In addition to implementing demand sensing, businesses can begin with sell-in data obtained from supply chain planning or an ERP system in supply chain management and then incorporate all relevant data sources and external factors to broaden the forecasting horizon.

3.4 Agile Supply Chain Management Practices

Agile supply chain management practices are a collection of methodologies and strategies emphasizing supply chain operations' adaptability, responsiveness, and flexibility. These practices involve utilizing real-time data analytics, collaborative planning, and other advanced technologies to enable businesses to respond swiftly to changes in customer demand, market conditions, and other external factors.

Adopting an agile model allows the organization to act swiftly and decisively and achieve successful business outcomes despite adverse conditions. Agile supply chain management practices can give companies greater visibility and control over their supply chains, enabling them to adapt more effectively and efficiently to fluctuating market conditions in the context of external factors influencing demand forecasting. By cultivating a culture of continuous improvement, innovation, and customer value, agile supply chain management practices have the potential to transform into modern supply chain.

4. Summing up

Demand forecasting accuracy is crucial for supply chain management and profitability. Manual forecasting methods hinder operational optimization and customer demand fulfillment. Customer satisfaction, purchasing decisions, and carrying costs suffer from inaccurate forecasting. In order to avoid these pitfalls, businesses can leverage statistical forecasting and collaborative demand. These methods recognize trends and patterns, optimize inventory levels, reduce over- and under-stocking, and improve customer service using advanced analytics and machine learning algorithms.

As the supply chain evolves and becomes more complex, businesses must adopt advanced demand forecasting techniques. Implementing these techniques will enable businesses to optimize their supply chain management by better-aligning supply and demand, resulting in increased productivity, decreased costs, and ultimately increased profits.

Read More

Warehousing and Distribution

Article | July 11, 2023

Explore the techniques to improve warehousing and distribution centre. Learn from the best books of logistics and distribution management and enhance warehousing operations and distribution processes.

Efficient warehouse management is crucial in the complex world of distribution and logistics. With various warehouse types serving different purposes, warehouse managers are responsible for ensuring smooth operations, safeguarding valuable goods, and optimizing supply chain units. Building a strong knowledge base is key, and the best way to start is by delving into the top warehouse management books. This article presents a curated list of essential reads that will provide you with a solid foundation in the warehouse and distribution field. From understanding fundamentals to exploring cutting-edge practices, these books help in better decision-making regarding warehousing and distribution operations.

1. Fundamentals of Warehousing & Distribution

Author Name: Material Handling Industry

Fundamentals of Warehousing & Distribution is an essential book for professionals in the warehousing and distribution industry. Published as part of the MHI Career & Technical Education Program, this series of four warehouse management books provides comprehensive knowledge on material handling equipment, information technology tools, and warehouse operations. Volume 1 serves as a foundational guide, introducing readers to modern warehouses and distribution centers' equipment, processes, and operations. With its focus on practical knowledge and industry best practices, this warehouse and distribution book provides readers with the skills and expertise necessary for successful warehouse and distribution management.

2. Warehousing and Distribution Practices

Author Name: xu ji ying

Divided into two parts, Warehousing and Distribution Practices covers seven key areas of the real-world processes for managing storage and implementation of effective distribution strategies. This distribution management book focus on essential knowledge and skills, each section provides valuable insights through logistics standard terms, case studies, knowledge links, and practical application. As one of the best books on logistics and distribution management, it will give you the complete step-by-step guidance to expand and improve warehousing and distribution centre by leveraging the theory shared by xu ji ying.

3. Warehousing And Distribution Management Project Type Tutorial

Author Name: Wang Yu

Warehousing and Distribution Management Project Type Tutorial, a logistics and supply chain management book, revolutionize logistics education with its innovative approach. This comprehensive book goes beyond traditional teaching methods, immersing readers in real-world scenarios and practical projects. Through eleven immersive teaching projects and thirty-two dynamic learning tasks, readers gain hands-on experience in system planning, business management, quality control, inventory operations, technology application, and more. Developed in collaboration with industry experts, this tutorial bridges the gap between theory and practice, empowering logistics professionals to navigate the complexities of warehouse and distribution management. With its unique project-based structure, this warehousing and distribution book delivers a transformative learning experience for aspiring logistics and supply chain industry leaders.

4. Fundamentals of Warehousing & Distribution: Volume 3

Author Name: MHI

Fundamentals of Warehousing & Distribution, a logistics and supply chain management book revolutionizes how logistics professionals perceive warehouses. By delving into captivating case study examples, this book unveils the intricacies of different warehouse configurations, showcasing how cutting-edge equipment and technologies empower diverse order fulfilment strategies. It challenges conventional wisdom by emphasizing that warehouses are no longer mere storage spaces; they have transformed into dynamic hubs that efficiently cater to a wide range of order types, from bulk shipments to individual products. With its ground-breaking insights and practical applications, this volume is a game-changer for industry experts seeking to elevate their warehousing and distribution management skills.

5. Warehouse Distribution and Operations Handbook

Author Name: David Mulcahy

Optimize warehouse operations with this warehouse and distribution management book, Warehouse Distribution and Operations Handbook. With a focus on improving inventory management, reducing costs and enhancing customer experiences, this handbook offers best practices, methods, equipment applications and technologies to utilize in different warehouse and distribution centres. Whether it's industrial, mail-order, or retail facilities, this comprehensive logistics and distribution management book provides the knowledge and strategies to drive profitability and control assets. It is an essential resource for anyone in the logistics industry looking to master distribution management and excel in warehouse operations.

6. Warehouse and Distribution Centre

Author and Editor Name: Robert Mulder & Michiel Kobussen

The warehouse and Distribution Centre is a valuable resource for logistics professionals and architects navigating the evolving landscape of warehouse design. This distribution management book addresses designers' pressing challenges, including cost control, technical requirements, and safety considerations. It offers a comprehensive system of theories, guidelines, and design standards, accompanied by a diverse collection of global warehouse and distribution centre projects. Balancing both the ends of practical reference and inspirational examples, this best book for distribution management equips readers with the knowledge and insights needed to create efficient, innovative, and sustainable warehouse and distribution solutions. It is a must-read for anyone involved in warehousing and distribution management.

7. Warehousing and Distribution Operation Practice

Author Name: peng jian cheng

Rooted in practical vocational education, Warehousing and Distribution Operation Practice is a book that emphasizes integrating theoretical knowledge with functional operations. It provides a hands-on approach to learning, enabling readers to apply their knowledge directly in real-world scenarios. This warehousing and distribution book will give you the required skills and expertise to optimize operational efficiency. With the help of practices shared by peng jian in the warehouse management book, readers will get insights into supply chain management and logistics operations. In addition, it will not only help in improving the processes in the warehouse and distribution but also enhance the overall business.

8. Operations and Supply Chain Management Essentials You Always Wanted to Know

Author Name: Vibrant Publishers & Ashley McDonough

Overcome the complexities of supply chain management and warehouse operations with Operations and Supply Chain Management Essentials You Always Wanted to Know. This engaging book takes you on a captivating journey through the interconnected world of logistics, unveiling the significance of every step in the process. Through a compelling narrative centred around a fictional company and its consumer product, you'll explore the challenges, decisions, and adaptations supply chain professionals face. Gain a deep understanding of supply chain operations, from disruptive forces to practical applications, and discover the importance of interactive business domains.

9. Start your Own Wholesale Distribution Business

Author Name: The Staff of Entrepreneur Media & Christopher Matthew Spencer

Embark on a lucrative journey in the distribution industry with 'Start Your Own Wholesale Distribution Business.' This comprehensive guide, crafted by the experts at Entrepreneur Media, equips you with the essential steps to establish a thriving wholesale operation from the comfort of your home. Discover the art of being an intermediary, connecting manufacturers and retailers to reap profits. Uncover industry-specific strategies, secure funding, identify profitable niches, forge valuable partnerships, and effectively market your business. With insights from experienced wholesale distributors, sample forms, checklists, and worksheets, this warehousing and distribution book is your roadmap to mastering the world of distribution and logistics.

10. Warehouse Management: The Definitive Guide to Improving Efficiency and Minimizing Costs in the Morden Warehouse

Author Name: Gwynne Richards

Discover one of the best books for logistics management in the modern era with 'Warehouse Management: The Definitive Guide to Improving Efficiency and Minimizing Costs in the Modern Warehouse.' This extensively updated fourth edition delves into the latest technologies, such as robotics, cobots, and AI, revolutionizing warehouse operations. Author Gwynne Richards offers expert insights and realistic solutions to optimize warehouse performance and improve efficiency. This effective distribution management book provides strategies and environmental initiatives to ensure a sustainable supply chain. Packed with real case studies and online resources, this book is an essential resource for distribution and logistics professionals.

Conclusion

Warehousing and distribution books have been a valuable resource for reference in the logistics field. While this compilation is not exhaustive, it offers a robust selection of warehouse management books that can effectively address various related challenges. Whether seeking insights into warehouse and transportation management or exploring other facets of supply chain management, logistics management, and procurement, the knowledge gained will be a worthwhile investment for future decision-making.

Read More

Supply Chain

Article | August 17, 2023

At Schneider Electric, meeting our customers’ expectations is a key priority. As concern over COVID-19 (Novel Coronavirus) grows, we are monitoring developments to this situation globally, as well as following local health and government regulations, continually assessing and responding to changes.

Our Business Continuity Plan (BCP) has been tested and implemented in geographies impacted. This plan includes health and safety, supply chain, lifecycle management services, and IT infrastructure.

Schneider Electric operations meet the criteria of an essential critical infrastructure as defined by most governments. While we do not anticipate interruptions to our operations, local governments may require temporary containment measures. In these cases, we comply with local laws, and in most cases seek support from local authorities to maintain critical business operations as an essential business for our communities.

Read More

Article | June 27, 2020

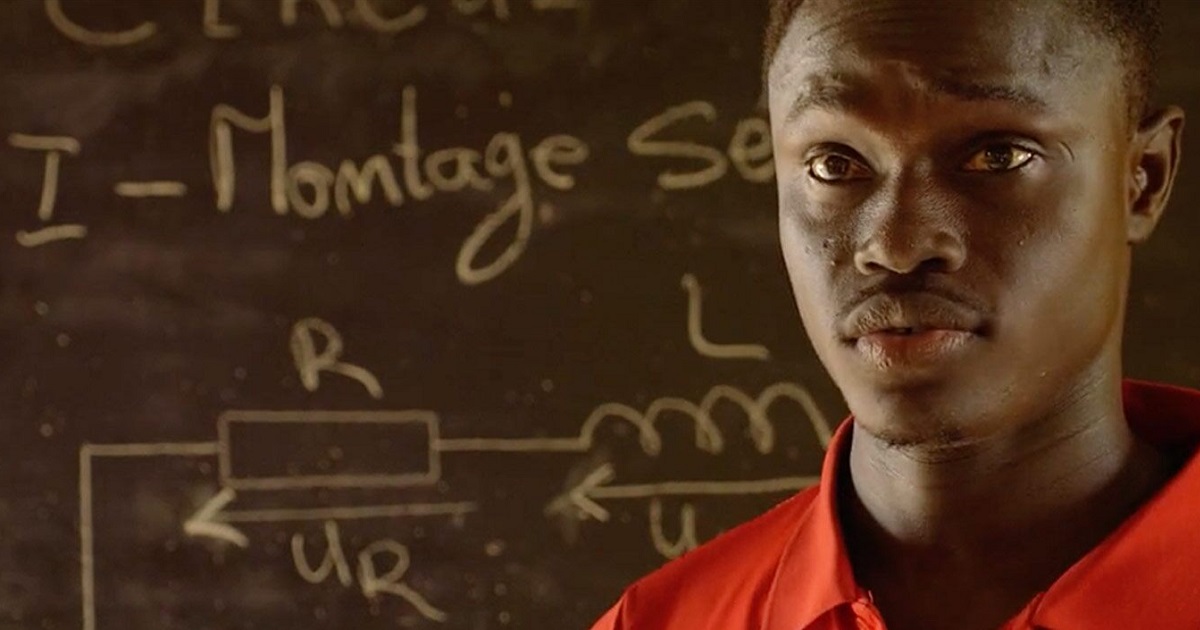

With half a million people benefited in 60+ countries, the Tomorrow Rising Fund is now focusing on education and professional training programs to secure the best future for young people and their communities affected by COVID-19.

Two months after launching the Tomorrow Rising fund to support Covid-19 emergency relief in April 2020, Schneider Electric’s Foundation moves forward to support recovery and resiliency through education and training programs.

The Tomorrow Rising Fund was launched to support emergency and longer-term reconstruction related to Covid-19 in all the countries where Schneider Electric operates. The Schneider Electric Foundation appealed to its leaders and employees to get involved and all their donations have been matched by the Group. Other external stakeholders and partners have also contributed.

Read More