Transportation

Article | April 26, 2023

Risk management has been a problem for as long as supply chains have existed. Because of the interdependence of all its connections, even a minor issue in one isolated region has the potential to jeopardize a whole global supply chain. As a result, when major global trends and events occur, the potential for widespread supply chain disruption is enormous.

Global supply chain risks and market disruptions have reached an all-time high. The most notable of them is the COVID-19 pandemic. In a 2020 survey, the Institute for Supply Management discovered that 95% of companies faced operational issues due to the pandemic. As a result, business executives all around the globe believe that if they want to be more resilient and competitive in the present market, they need to modernize and make significant changes to their supply chain strategy.

Other recent factors that have had a significant impact on traditional supply chain practices include the fast pace of change in consumer behaviors and a pretty unstable trade and political environment.

In the last ten years, e-commerce spending has tripled, and internet shopping had increased by 149% in 2020 compared to the previous year. With the growth of e-commerce, there has been a rise in customer demand for faster delivery and more personalized shopping experiences. The Amazon Effect refers to the growing expectation for same-day delivery and its effect on businesses and logistical networks. To be resilient enough to react to these rising demands, supply chain managers have had to make fast and significant modifications to their logistics and warehousing networks, as well as discover new ways to collaborate with third-party fulfillment partners.

Even before the impact of COVID-19, American businesses were attempting to reduce their dependence on foreign manufacturers and suppliers. Foreign tariffs and trade policies had become more unpredictable by 2019, and businesses were seeking technological solutions to make the supply chains more self-sufficient and resilient. As a result, integrating digital transformation and Industry 4.0 technology into supply chain operations is quickly becoming a top concern for global business leaders.

How does Supply Chain Resilience Work?

A flexible contingency plan and the ability to react swiftly to operational disruptions are important characteristics of effective supply chain management. However, to be truly resilient, a supply chain must be able to predict and anticipate disruptions and, in many cases, avoid them entirely.

Strategic supply chain planning is an important step in achieving resilience because it synchronizes all supply chain components and increases visibility and agility. Supply and demand needs are better understood, and production is synchronized due to supply chain planning. This integrated, forward-thinking approach assists businesses in better anticipating problems, reducing the impact of supply chain disruptions, and improving overall operations.

When a business has the digital systems to analyze and make sense of Big Data, it significantly improves supply chain resilience. Artificial intelligence-enabled systems can curate disparate data sets from across the business and the globe. To discover trends and opportunities, news, competitor activity, sales reports, and even customer feedback can be examined together. The system's connected devices are constantly monitored, providing real-time insights about where and how processes can be automated and improved. For instance, AI, machine learning, and modern databases acquire and handle Big Data and analyze and learn from it in an almost infinite number of ways. This enables intelligent automation across the network and provides supply chain managers with the real-time insights they require to respond quickly to disruption and unexpected events.

Supply chain managers have traditionally sought to limit the number of partners and suppliers in their network to minimize operational and logistical complexity. This approach is based on the stability of the social, environmental, and political systems. Unexpected disruptions in one region can slow or even stop network operations across the board. Supply chain resilience technologies, such as blockchain, sensors, and advanced analytics, enable supply chain managers to monitor complex partnerships and supplier contracts even in the most remote parts of their network.

Profitability in the supply chain has always been dependent on minimizing excess and keeping inventories as lean as possible. Capacity and inventory buffers are expensive, and supply chain managers have often bet against disruptions to keep prices low. When the pandemic struck, many businesses discovered the real cost of the gamble. Supply chain operations can involve on-demand manufacturing, virtual inventories, and predictive demand forecasting using digital supply chain technologies to remain resilient, even in times of unexpected disruption.

Benefits of a Resilient Supply Chain

Finding a successful balance between supply and demand is a significant issue for any supply chain manager in an increasingly competitive market. Many businesses that have cut costs on diversification, supply chain technology, and other resilience measures have lately discovered the true cost of those choices. However, when businesses engage in diversification, supply chain technologies, and other resilience measures, they can achieve a variety of business benefits, including:

More efficient operations: Better resilience often results in less risk and a greater capacity to invest in innovation and growth. For example, according to a 2020 global business analysis conducted by Bain and Company, businesses that prioritized their investment in supply chain resilience had up to 60% quicker product development cycles and were able to increase production capacity by up to 25%.

Enhanced productivity: Resilient supply chain solutions lead to the overall system increased productivity. According to a McKinsey 2020 survey, supply chain leaders from across the world report increased productivity due to resilient supply chain systems, and 93% of those surveyed plan to prioritize resilient supply chain strategies for investment in the next year.

Risk reduction: Supply chain activities are often the most vulnerable to risk and loss in many businesses. Supply chains, by nature, are geographically distributed and functionally complex. As a result, supply chains are particularly vulnerable to risk. Resilient supply chain technologies minimize risk by providing insight into all network operations and enabling companies to improve and adjust their processes and logistics in real-time.

Technologies for an Agile Supply Chain

Digital transformation and modern supply chain technology provide businesses with the resilience and competitive advantage they need to react swiftly to disruptions and opportunities.

Artificial intelligence (AI): AI-powered supply chain systems can offer deep procedural and operational insights by gathering and analyzing data from many sources. Predictive analytics and Big Data analysis can assist in predicting risk and demand and recommending measures and reactions in the company.

Machine learning: Machine learning enables the discovery of patterns in supply chain data and the identification of these influential factors - all while constantly learning. This enables supply chain managers to react fast with the finest workflows and operational strategies available.

Industrial Internet of Things (IIoT): The IIoT network in a supply chain comprises connected devices and objects with sensors and unique IDs that allow them to transmit and receive digital data. They collect information and communicate with the central system. AI can analyze and understand this data to enable quick decisions and intelligent automation of supply chain operations and procedures.

Additive (3D) printing: Smart factories can quickly reprogram 3D printers to produce specific products on-demand without disrupting regular business operations in the long run. The accessibility of potential virtual inventories enables supply chains to defend themselves against disruption.

Robots and autonomous things: Robots and drones, which are intelligently automated for speed, efficiency, and accuracy, can adapt their operations on the go to meet quickly changing requirements. They also reduce the risk of harm by eliminating overly repetitive or dangerous tasks from human workers.

Modern databases: The resilient supply chain solutions rely on Big Data, advanced analytics, and real-time insights from modern databases. Supply chain technology can be improved to operate faster and most resilient when equipped with a modern ERP system and an in-memory database.

Resilience means more than just surviving a disruption in operations. A fully resilient supply chain and businesses survive hardship and use it to innovate and improve their business. Building a resilient supply chain is very important in this modern era because disruptions like a pandemic, wars, climate change, etc., are occurring a lot these days. A resilient supply chain helps businesses to survive and thrive even during tough times. To read more about ways to boost supply chain performance, click here.

FAQ

What is supply chain resilience?

Supply chain resilience refers to the supply chain's capacity to be prepared for unexpected risk events, react and recover swiftly to potential disruptions, and grow by shifting to a new, more desirable state in order to improve customer service, market share, and financial performance.

How is supply chain resilience measured?

A supply chain's resilience index is calculated by aggregating its company's resilience index. Given that supply chain company's performance influences overall supply chain performance, supply chain resilience should be measured using the companies' resilience index.

{

"@context": "https://schema.org",

"@type": "FAQPage",

"mainEntity": [{

"@type": "Question",

"name": "What is supply chain resilience?",

"acceptedAnswer": {

"@type": "Answer",

"text": "Supply chain resilience refers to the supply chain's capacity to be prepared for unexpected risk events, react and recover swiftly to potential disruptions, and grow by shifting to a new, more desirable state in order to improve customer service, market share, and financial performance."

}

},{

"@type": "Question",

"name": "How is supply chain resilience measured?",

"acceptedAnswer": {

"@type": "Answer",

"text": "A supply chain's resilience index is calculated by aggregating its company's resilience index. Given that supply chain company's performance influences overall supply chain performance, supply chain resilience should be measured using the companies' resilience index."

}

}]

}

Read More

Warehousing and Distribution

Article | June 27, 2023

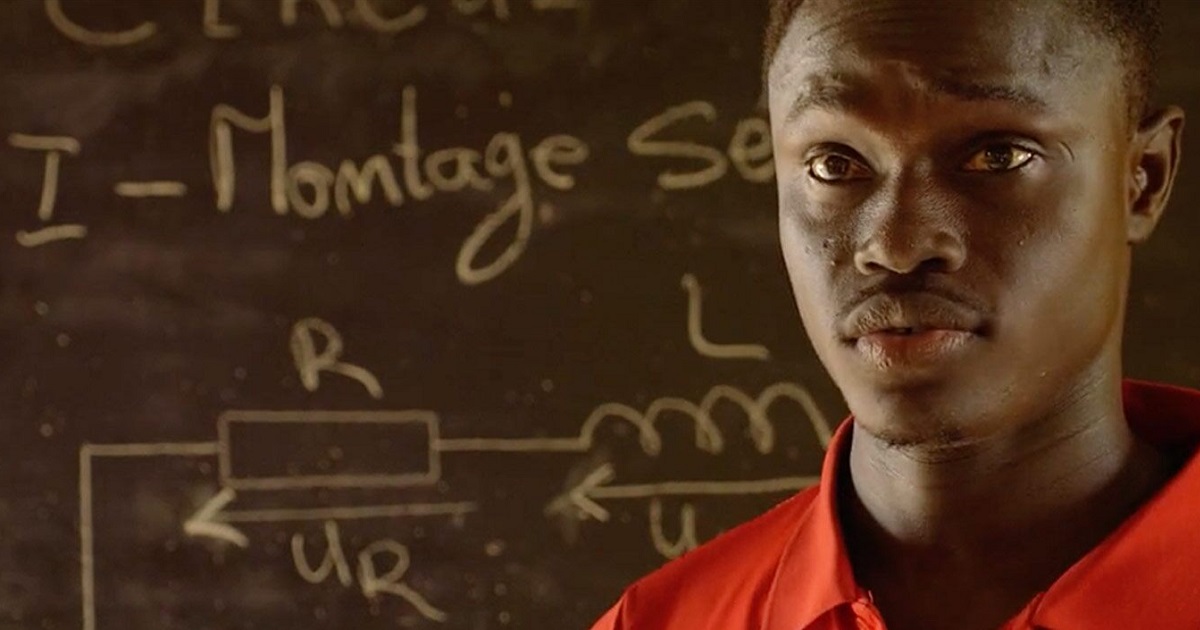

With half a million people benefited in 60+ countries, the Tomorrow Rising Fund is now focusing on education and professional training programs to secure the best future for young people and their communities affected by COVID-19.

Two months after launching the Tomorrow Rising fund to support Covid-19 emergency relief in April 2020, Schneider Electric’s Foundation moves forward to support recovery and resiliency through education and training programs.

The Tomorrow Rising Fund was launched to support emergency and longer-term reconstruction related to Covid-19 in all the countries where Schneider Electric operates. The Schneider Electric Foundation appealed to its leaders and employees to get involved and all their donations have been matched by the Group. Other external stakeholders and partners have also contributed.

Read More

Supply Chain

Article | May 22, 2023

Purchasing software and supply chain management software are often mistaken for one another, but both have distinct functionalities. While purchasing software automates the procurement process, supply chain management software executes logistical transactions and manages supplier relationships. This report identifies the similarities and differences between the two software categories to help you understand which one is better suited to your needs.

What is purchasing software?

Purchasing software is an online tool that allows businesses to automate the process of procuring goods and services. It includes security compliance and reporting features.

Purchasing solutions offer integrated tools for invoice approval, inventory control, asset management, customer service, and work order management. They help manage contracts, analyze spending, track sales deliveries, and monitor inventory levels. They also assist in identifying bottlenecks in the purchase process, such as functions that have high expenditure.

Purchasing software offers invoice processing capabilities as well. Procurement professionals and accounting teams can use the tool to generate invoices, track invoice status, and monitor expenses via detailed reports.

What is supply chain management software?

Supply chain management software is a software platform that allows supply chain managers to automate the entire supply chain process—from acquiring raw materials to delivering the finished goods to consumers. The software provides tools for monitoring stock levels, including raw materials, and predicting future requirements based on the current inflow and outflow of inventory.

Supply chain management tools manage material handling, order fulfillment, and information tracking for stakeholders such as manufacturers, suppliers, and transport and logistics providers. They also track the returns of damaged goods, process refunds and insurance claims, and provide planning and forecasting tools for supply chain professionals.

What do they have in common?

Purchasing is a crucial component of supply chain management. Together, these processes significantly contribute to an organization’s procurement cycle. Despite the functionality differences, both the software categories have a few features in common, including supplier management, order management, and forecasting.

Which tool is right for you?

The answer to this question depends on your use case. If you’re looking for a tool that majorly focuses on acquiring supplies, opt for a purchasing software solution, as it will help you streamline the procurement cycle, maintain purchase order accuracy, and monitor supplier activities. However, if you wish to manage your entire supply chain operations, including supplier, transportation, warehouse, and inventory management, then investing in a supply chain software solution would be the right choice.

Read More

Supply Chain

Article | November 11, 2022

The complexity of today’s supply chain has resulted in a highly fragmented supply chain ecosystem. Whether it is a global pandemic or an ongoing war, streamlining the moving parts in the supply chain management system is an immense feat in the current climate. The resulting shortage of materials, disruption of transportation, and delays have complicated the supply chain even further. Add to it the expectation to minimize expenses, optimize inventory, and enable quality and customer expectations, and stakeholders at every level of the supply chain are inundated with challenges.

This is where using advanced analytics in supply chain can be a game changer for many manufacturers. It can help them gain a deeper insight into their operations and how the supply chain is moving.

How Supply Chain Analytics Enriches Supply Chain Management

A 360-degree view of the supply chain is crucial for supply chain leaders. A lack of insight can cause costly delays and avoidable disruptions. Obtaining complete visibility in supply chain management, on the other hand, can be difficult. The immense volume of data that many organizations have to deal with makes it difficult to gain proper insight.

Supply chain analytics tools help in gaining a better sense of the aggregated data from different parts of the supply chain, such as procurement, ERP in supply chain management, warehousing management, shipping and logistics management, and many more. The more accurate the data is, the simpler it is to use advanced supply chain management analytics to forecast, predict, and plan better in order to maximize the supply chain’s capabilities.

Optimizing the Supply Chain: 3 Ways to Do so with Analytics

With the range of analytics applications in supply chain in use today, manufacturers have the opportunity to completely transform how to view, manage and strategize. Here are five data analytics supply chain tools to consider in the pursuit of optimization.

Demand Forecasting

Inventory management is at the heart of supply chain optimization. Not calibrating the inventory stock based on demand and supply for bestselling products and those that don’t move fast can cause either an overstocking or understocking problem. Either way, forecasting the right balance is difficult to achieve, but data analytics can make it simpler. The lack of the right products in stock can heavily impact the bottom line. According to a survey by Logility, 36% of supply chain experts consider inventory optimization the primary reason for adopting analytics. An integrated mapping of retail sales, inventory levels, and the flow of goods will lead to accurate demand forecasting.

This data can empower organizations to:

Strategize sales promotions

Define product pricing

Maximize budgets

Predict accurate inventory levels

Inventory management has a cascading effect on the supply chain, and advanced demand forecasting has helped many organizations achieve an optimum level of inventory for the right products.

Predictive Warehousing Maintenance

Machine Learning (ML), artificial intelligence (AI), and the Internet of Things (IoT) have been emerging technologies on the supply chain management landscape. By using a mix of these technologies, it is possible for manufacturers to deploy predictive maintenance in warehousing. Predictive maintenance is the process of assessing data generated from the past and in real-time to determine patterns and identify equipment failure and maintenance schedule before a breakdown occurs.

This helps manufacturers to:

Avoid heavy repair costs

Plan spare part supply

Slash downtime from equipment failure

Eliminate production delays

In addition to reducing production bottlenecks, predictive maintenance gives businesses the ability to manage their equipment and optimize their shelf-life.

Warehousing Efficiency

At the warehouse phase of the supply chain, analytics can help manage the supply chain in more than just one way. The warehouse workflow is just as crucial, as it facilitates a clear view of the condition of goods as well as the optimization of the warehouse space. In addition to warehouse space maximization, quality control is another challenge that warehousing management addresses.

Supply chain analytics can enhance warehousing efficiency by:

Ensuring the correct storage of goods based on their weight, fragility, and perishability

Aligning with resource management like equipment, vehicles

Identifying disruptions to storage before they occur

One of the advantages of supply chain analytics is getting a deep insight into the warehouse’s operation so manufacturers can identify gaps and take steps to make it more efficient.

Transportation Tracking

Real-time analytics of transportation and logistics is a crucial piece in the puzzle of supply chain management. For example, the data generated in relation to fuel consumption, weather conditions, and even traffic patterns can help organizations boost their logistics and carrier management.

It can help them to:

Schedule deliveries

Determine better routes

Evaluate current routes

Strategize their shipping schedule

To Wrap it Up

To put it simply, a deep insight into the supply chain, inventory management, and warehouse operations is a great way to ensure the supply chain is on track. Effective supply chain management software is an asset for an organization when it is able to leverage the insights and make well-informed strategies to further optimize the supply chain.

Read More