Management

Article | June 21, 2023

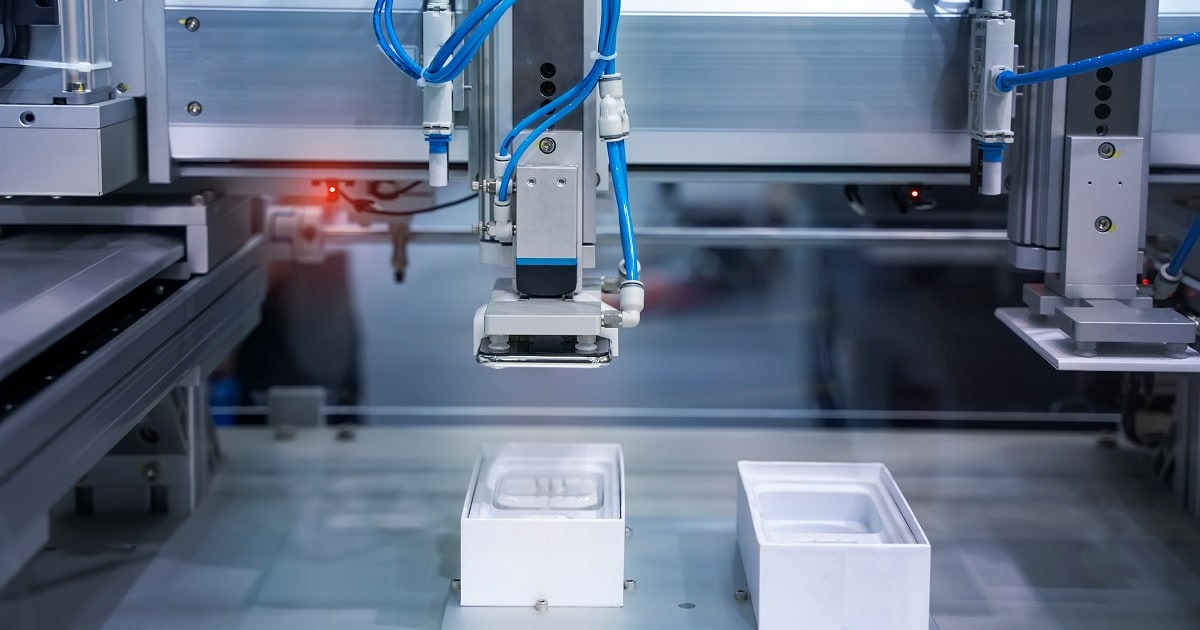

Transform the supply chain with cutting-edge warehouse automation tools. Enhance productivity, minimize costs, and deliver exceptional customer experiences to stay ahead in the competitive market.

In the rapidly evolving world of manufacturing, logistics, and supply chain management, adopting automation has become imperative for businesses aiming to maintain a competitive edge. By minimizing costs, enhancing efficiency, and reducing downtime, automation delivers optimal value for manufacturers. However, selecting the right partner can be challenging with numerous warehouse automation companies available. This article explains the features and benefits of top ten warehouse automation tools that offer expertise in improving business operations. These data warehouse tools provide comprehensive solutions to meet diverse needs of the logistics and warehousing companies and improve the supply chain performance.

1. 3PL WMS Software Solution

3PL WMS Software Solution is one of the leading warehouse automation tools for supply chain operations. This software has comprehensive features that automate and streamline warehouse processes, offering unprecedented efficiency. The tool seamlessly integrates with existing systems and provides total transparency and control. 3PL warehouse automation software boosts order throughput, reduces pick time, and automates billing effortlessly. Gain unprecedented insights through accurate, real-time reporting, ensuring inventory accuracy and reducing lost-inventory costs. This warehouse automation tool, designed as the warehouse management backbone, revolutionizes operations, enhances customer satisfaction, and drives exponential growth.

2. Datex 3PL WMS

Datex 3PL WMS offers the most innovative warehouse management tools that help implement warehouse automation in the supply chain process for transportation services. This software empowers transportation and logistics services, revolutionizing material handling, storage, trans-loading, cross-docking, and more. It supports diverse industries such as refineries, steel mills, and energy distribution facilities. Its flexibility makes it an optimal solution to handle any inventory type, including bulk materials, steel products, liquids, and hazardous materials. This automated warehouse software also enables multi-warehouse operations and accommodates various modes of transportation. Additionally, Datex 3PL WMS boasts a highly flexible billing system, allowing individualized billing strategies and capturing value-added services. Industry experts benefit from streamlined processes, improved efficiency, and accurate billing, ultimately enhancing their supply chain business and warehouse operations.

3. Deposco

Deposco Bright Warehouse is a game-changing warehouse management software solution that offers advanced features and capabilities to businesses of all sizes. This data warehouse tool empowers companies to pick, pack, and ship orders efficiently, optimizing processes to further improve order fulfillment while reducing operational costs. It provides strategic order allocation, workgroup segmentation, and optimized picking strategies, to achieve accurate and speedy order fulfillment. The software offers network-wide inventory visibility through advanced tracking, barcoding, and management capabilities. This solution automates shipping processes by seamlessly integrating with carriers, ensuring maximum accuracy and speed. Leveraging its material handling technology for automation can lead to significant productivity improvements. Businesses can enhance their capabilities by accessing a unified view of operations, utilizing customization options, and benefiting from direct API integration with shipping carriers.

4. Softeon

Softeon is a powerful warehouse management tools for supply chain automation. Its comprehensive WMS optimizes distribution operations, handling all essential tasks while offering unique functionality for a competitive edge. With a proven deployment success rate and flexible delivery options in the cloud or on-premise, Softeon empowers businesses to streamline inventory management and delivery processes. By integrating with their Warehouse Execution System (WES), warehouse and distribution companies can further enhance order fulfillment orchestration and optimization. Industry leaders like UPS Supply Chain Solutions and Sears Home Services rely on this warehouse automation software.

5. Logiwa WMS

Logiwa WMS offers a cloud fulfillment platform that combines WMS software and order fulfillment capabilities, enabling companies to operate a digital fulfillment network and expand their direct-to-consumer operations without the need for additional staff. The data warehouse management tool offers comprehensive warehouse and inventory management functionality, billing, and seamless integrations with over 200 ecommerce, accounting, and shipping solutions; it empowers 3PL providers to optimize order fulfillment, enhance speed and accuracy, and drive customer satisfaction.

6. SnapFulfill

SnapFulfill is one of the leading warehouse management technologies that empower companies across various industries, including B2C and B2B retail, third-party logistics, manufacturing, food and beverage, and electronics, to optimize their inventory, space, and resources. With SnapFulfill's class-leading warehouse management solutions, businesses can streamline operations and enhance efficiency. The software offers flexible deployment options and payment methods for diverse warehousing challenges. By utilizing SnapFulfill, industry experts gain access to advanced data warehouse tools that enable them to improve their supply chain business, enhance warehouse and distribution processes, and achieve optimal inventory management for increased productivity and profitability.

7. Indigo Software

Indigo WMS is an award-winning warehouse management system tool designed to enhance supply chain operations. It offers real-time control, visibility, and functionality for all warehouse processes. It is one of the best supply chain tools to track inventory in real-time, enabling efficient cycle counting, forward pick replenishment, and improved inventory forecasting. With Indigo WMS warehouse automation software, these tasks are automated, and the software ensures greater picking accuracy, reduces returns, and enables on-time and complete deliveries. It seamlessly integrates with existing systems, whether from SAP, Microsoft, Oracle, Infor, Sage, or other ERP, TMS, or SCP vendors, providing live and up-to-date data visibility across the entire supply chain process.

8. OrderWise

OrderWise is an order management system that empowers businesses in the consumer goods and retail sector to accelerate operations and deliver exceptional customer service. With its integrated features, OrderWise ensures seamless order processing and maximizes sales opportunities. By tracking orders from various sales channels, managing tight schedules, and making real-time adjustments, businesses can meet customer demands promptly. This is one of those supply chain management tools that provides valuable insights into customer purchase history and stock availability, enabling personalized recommendations and enhancing sales effectiveness. Whether for ecommerce, retail, or B2B sales, OrderWise streamlines order operations, making them smoother, faster, and more accurate.

9. Balloon One

Balloon One provides supply chain management tools, offering tailored software solutions to distribution, manufacturing, and e-commerce businesses. Its expertise lies in streamlining processes, optimizing resource allocation, and enhancing operational efficiency. With a focus on minimal disruption, Balloon One seamlessly implements software solutions, ensuring uninterrupted business operations. As an impartial advisor, the software offers both SAP Business One and NetSuite, thus allowing to recommend the ideal ERP system for each company's unique requirements. In addition, this software provides wholesale and distribution businesses with the robust HighJump WMS, a real-time warehouse management system that delivers scalability and flexibility.

10. Foxfire

Foxfire offers supply chain management tools specializing in Warehouse Management Systems (WMS). It offers WMS solutions, including features to optimize inventory, increase labor productivity, and enhance customer satisfaction. With over 20 years of industry experience, Foxfire has a proven track record of delivering measurable results to customers worldwide. This tool provides a comprehensive approach, including needs assessment, best practice recommendations, training, and ongoing support. Additionally, it is cost-effective by delivering low lifetime costs.

Conclusion

The warehouse automation market is experiencing significant growth, with a wide array of exceptional warehouse automation tools that offer high-quality solutions. Regardless of any special requirements, exploring the features of each warehouse automation tools is vital to identify the ideal fit for any business. Choosing the correct solution from the data warehouse tools list will help to improve inventory management and distribution efficiency through warehouse automation. Embrace the opportunity to streamline processes by leveraging supply chain management tools and warehouse automation solutions and experience the transformative power of automation to unlock the full potential of your business.

Read More

Warehousing and Distribution

Article | July 11, 2023

Supply chain is the backbone of any business. Since there is a supply chain in existence, you can buy whatever product you want. The supply chain is evolving since the Industrial Revolution, and it is still changing, and the evolution journey is fascinating. Before moving forward with the article, first, let's understand supply chain and supply chain management.

What is a Supply Chain?

A supply chain is an entire process of producing and selling commercial goods, beginning with the procurement of raw materials and ending with the distribution and sale of the goods. The supply chain ensures that a product is available in the right place, at the right time, and the lowest possible cost while ensuring the product quality. The supply chain aims to provide the maximum value to the customer at the minimum likely costs. The supply chain is the single most significant expense for businesses, and it provides them with a tremendous opportunity to improve and increase savings and profit margins. The price of most products is competitive in the market, but the supply chain determines the product's profit margin. The demand for products and services fluctuates for various reasons, and meeting this fluctuating demand with a higher degree of quality requires knowledge of supply chain management. Effective supply chain management is essential for any business to compete in the market.

What is Supply Chain Management?

Supply chain management is an essential factor in a business's long-term success. The management of how goods and services evolve from raw materials to products sold to consumers is known as supply chain management. It includes the processes of transporting and storing raw materials, storing finished goods until they sell, and tracking where sold goods go so that you can use the data to boost future sales. Supply Chain Management includes all aspects of business activities, including logistics, purchasing, and information technology. Materials, finances, suppliers, manufacturing plants, wholesalers, retailers, and consumers are all combined into a single system. A business with a well-managed supply chain can significantly reduce all operating costs associated with that chain, resulting in higher profits. The main goal of effective supply chain management is to increase profitability by improving customer satisfaction and reducing business costs. Profits improve as expenses are in control and reduced when possible. When the costs of purchasing raw materials and manufacturing goods drop, the operating costs also decrease.

Challenges in Supply Chain Management

There are many challenges related to supply chain management. In this section, we will focus on some of the most significant supply chain management challenges.

• Visibility: It is a significant issue in supply chain management. Businesses are unable to track all international cargo. The majority of data on the ocean or air shipments is often unavailable. Between 2008 and 2016, an average of 600 containers lost at sea (it does not include catastrophic incidents). These figures are concerning because the amount of cargo shipped over time is rapidly rising.

• Uncertainty: Uncertainty has been difficult in supply chain management. Demand planning is essential because many businesses have massive amounts of leftovers. If it is perishable, it is thrown away. There is a lot of waste, and it's all because of bad planning. In addition, initial raw materials may be unreliable, or lead time may be unpredictable. It isn't easy to be confident of any part of the supply chain, mainly because it is an extensive system.

• Customer Service: Supply chain management is all about getting the right product to the correct location at the right time. It seems easy at first, but it can quickly become complicated.

• Cost Management: Increasing energy/fuel and freight costs, a more significant number of global customers, technology, rising labor wages, new regulations, and rising commodity prices all strain operating costs.

• Planning and Risk Management: Annual reviews and redesigns are needed to be efficient and effective. These changes are in reaction to market changes, such as new product releases, global sourcing, credit availability, and the need to protect intellectual property. To monitor and minimize these threats, they must be identified and quantified.

• Supplier/Partner Relationship Management: It is crucial to create, understand, and follow mutually agreed standards to understand current performance and areas for improvement better. Using two separate approaches to measure and communicate performance results is a waste of time and resources. Trusting the system that was in place to ensure consistency and better supplier/partner relationships is necessary.

Emerging Trends in Supply Chain

The supply chain process is continuously evolving. The emerging supply chain and logistics trends prioritize intelligent, tech-driven management to minimize operational costs and enhance efficiency. The logistics and supply chain aspect is vital for any business in supplying high-quality raw materials, ensuring an efficient manufacturing process, and tracking, shipping, and storing finished goods.

Companies that implement well-designed supply chain practices can satisfy customer needs more quickly and efficiently. This improves customer relationships and loyalty, resulting in increased revenue and the acquisition of new customers through positive word of mouth.

Let's look at some significant emerging trends that are expected to shape and develop supply chain operations in the future.

Digitization of Supply Chains

Digitization is the process of reinventing logistics operations by combining the latest technology with other physical and digital assets. Digitization allows us to better adapt to the fast-paced, highly competitive, omnichannel business environment.

Digitization increases the speed, dynamics, and resiliency of supply chain operations, resulting in improved customer responsiveness and, ultimately, increased revenue. Companies that embrace digitalization can gain genuine value, improved revenue, and market valuation.

Companies should significantly redesign their supply chain strategy to gain the full benefits of digitization. It is not enough to decorate it with digital technology.

The Internet of Things (IoT) occupies a significant position in digitalization as a highly transformational technology solution in the logistics sphere. The Internet of Things (IoT) is a network of interconnected computing devices that allows data to be sent over networks without human input. It assists businesses in monitoring inventory, managing warehouse stock, optimizing fleet routes, and reducing dead miles.

Artificial Intelligence

Advanced Artificial Intelligence solutions have several uses in the supply chain, particularly in the warehousing area. The procurement process involves using gesture recognition solutions instead of keyboard and mouse. It also includes self-driving vehicles, which are designed to navigate without human assistance.

In the supply chain, the concept of robotics and automation is widely implemented. The new generation of robots is easier to program, more flexible, and more affordable. Their job is to help employees with repetitive and physically challenging tasks.

Enhanced Supply Chain Visibility

Proper supply chain data analysis can significantly boost business forecasting and decision-making. It can also optimize the use of inventory management, storage, and transportation resources.

Supply chain visibility provides information on what is happening at each stage of the supply chain. It is crucial for the overall efficiency of the supply chain process, which includes sourcing, manufacturing, transportation, and delivery.

Real-time inventory management is one of the advantages of enhanced chain visibility. It uses mobile point-of-sale systems and sensors, and it elevates inventory management to a whole new level.

For example, instead of paying for purchased goods at a store, customers can take the desired products and have the products immediately charged to their credit and debit cards. Furthermore, real-time inventory management allows for the replacement of goods as they are consumed.

Circular Supply Chain

The term "linear supply chain" refers to the traditional concept where goods travel in a straight line (from raw material to finished product). Modern logistics techniques are focused on the circular supply chain idea, which involves reusing previously, used products as raw materials.

Reusing products and materials is referred to as reverse logistics, and it is a novel and innovative technique. It assists businesses in reducing administrative and transportation expenses, increasing sustainability, improving customer service and loyalty, creating value, and conserving resources.

Used products can be kept in circulation if businesses work together with their suppliers and customers.

More focus on Risk Management and Supply Chain Resiliency

Without a doubt, companies must seriously consider supply chain risk management as a means to prepare for unfavorable circumstances. The increasing use of outsourcing, offshoring, product versatility, supply chain security, and significant interdependence across the supply chain highlights the need to deal with risks in the supply chain.

However, no matter how solid the plan is, it cannot prevent errors from happening. Here's where supply chain resilience comes into play. It is an accurate indicator of a company's ability to survive disruptive circumstances.

Visibility throughout the supply chain is necessary to detect disruptions, close collaboration with suppliers and distributors so that alternative supply routes can be found, and a good incident response plan to provide a course of action when disruption occurs are all steps that are important to make the supply chain more flexible and resilient.

Use of SaaS in the Supply Chain

The software-as-a-service (SaaS) Sapproach is growing in popularity in supply chain technology and logistics management and the growth of cloud computing. This is primarily due to SaaS's security and safety and the convenience of paying for precisely the services you require. Companies can avoid the high fixed costs of system maintenance, upgrades, and infrastructure-related expenditures by using SaaS.

Supply chains are continuously evolving technology, and the diversity of employee skill sets is playing an essential role in this evolution. Organizations are becoming more conscious of changes in their market competition and continuously updating or even reinventing their market offering to maintain and develop their market positioning.

Many companies are already turning to technology to improve their supply chain operations; however, before new systems are implemented and employees are upskilled to adapt to new ways of working, existing processes must be reviewed to eliminate waste activities from the supply chain, and data must be cleansed. To meet consumer demands, supply chains must be constantly checked for efficiency improvements and aligned with corporate strategy. At present, many organizations are reviewing the length of their supply chains, intending to minimize the overall size and bring supply chains closer to the organization or the end consumer, reduce risk exposure, eliminate waste, and align with corporate strategy.

FAQ’s

• What are the three foundations of supply chain?

The three foundations of a supply chain are strategy, service, and cost. Aligning the strategy, service and cost is essential to support your company’s overall business growth and objectives. A good strategy along with good service and reduced costs helps in increasing profitability and customer satisfaction.

• What are the pillars of supply chain?

Plan, Source, Make, Deliver and Return are the pillars of supply chain.

Planning involves strategies and methods to be planned, Sourcing means procuring raw materials and other services, Making means manufacturing, Deliver means ensuring that the products reach the customers on time and Return means post delivery customer support that is associated with all kinds of returned products.

• Why supply chain management is important?

The management of how goods and services evolve from raw materials to products sold to consumers is known as supply chain management. It includes the processes of transporting and storing raw materials, storing finished goods until they sell, and tracking where sold goods go so that you can use the data to boost future sales. A business with a well-managed supply chain can significantly reduce all operating costs associated with that chain, resulting in higher profits. The main goal of effective supply chain management is to increase profitability by improving customer satisfaction and reducing business costs.

{

"@context": "https://schema.org",

"@type": "FAQPage",

"mainEntity": [{

"@type": "Question",

"name": "What are the three foundations of supply chain?",

"acceptedAnswer": {

"@type": "Answer",

"text": "The three foundations of a supply chain are strategy, service, and cost. Aligning the strategy, service and cost is essential to support your company’s overall business growth and objectives. A good strategy along with good service and reduced costs helps in increasing profitability and customer satisfaction."

}

},{

"@type": "Question",

"name": "What are the pillars of supply chain?",

"acceptedAnswer": {

"@type": "Answer",

"text": "Plan, Source, Make, Deliver and Return are the pillars of supply chain.

Planning involves strategies and methods to be planned, Sourcing means procuring raw materials and other services, Making means manufacturing, Deliver means ensuring that the products reach the customers on time and Return means post delivery customer support that is associated with all kinds of returned products."

}

},{

"@type": "Question",

"name": "Why supply chain management is important?",

"acceptedAnswer": {

"@type": "Answer",

"text": "The management of how goods and services evolve from raw materials to products sold to consumers is known as supply chain management. It includes the processes of transporting and storing raw materials, storing finished goods until they sell, and tracking where sold goods go so that you can use the data to boost future sales. A business with a well-managed supply chain can significantly reduce all operating costs associated with that chain, resulting in higher profits. The main goal of effective supply chain management is to increase profitability by improving customer satisfaction and reducing business costs."

}

}]

}

Read More

Warehousing and Distribution

Article | July 11, 2023

Autonomous robots have transitioned from a futuristic system that only a few enterprises could afford to a sustainable, well-established solution in a wide assortment of warehouse automation projects in recent years.

With the flourishing transportation and logistics industry and increasing e-commerce penetration worldwide, innovative technologies are revealing promising opportunities throughout the supply chain.

Warehouse Automation: Driving Value in the Supply Chain

Historically, autonomous robots have been used to perform tedious and repetitive tasks, necessitating sophisticated programming for setup and incorporation while lacking the dexterity to easily adjust operations.

As autonomous robots become more intelligent, their setup times decrease, they need less monitoring, and they are able to work alongside their human counterparts. The benefits for the future supply chain are increasing as autonomous robots become more capable of working day and night with more consistent levels of productivity and quality and performing tasks that individuals should not, cannot, or do not want to do.

Autonomous robots drive advancements and add value to the supply chain, primarily by increasing revenue potential and lowering direct and indirect operating costs. Autonomous robots, in particular, can assist:

Boost efficiency and productivity.

Lower risk, error frequency, and rework rates.

Enhance employee safety in high-risk workplaces.

Handle low-value, routine tasks so people can work together on strategic projects that can't be done by machines.

Raise revenue by optimizing order fulfillment rates, and delivery speed, and, ultimately, increasing customer satisfaction.

Sneak Peek into the Future of Autonomous Robot

Autonomous robots are expected to witness strong growth in the coming years. These robots will become more common in the future supply chain as technology advances, allowing them to operate with more human-like abilities. Improvements in haptic sensors, for example, will enable these robots to grasp objects varying from multi-surfaced metal assembly parts to fragile eggshells without requiring changes to robotic components or programming. This will encourage companies operating in the industry to increase their research and development activities and introduce innovative and advanced supply chain technologies.

Read More

Article | April 17, 2020

Supply chain peak season technology aids supply chain leaders in understanding their operations, unlocking insights, reviewing performance, and much more. In conjunction with the rise of e-commerce and ongoing demand for more products, faster service, and better supply chain performance, the entire year begins to take on the characteristics of supply chain peak season which traditionally has occurred during the time period after Labor Day through returns season in January.

Read More