Warehousing and Distribution

Article | June 27, 2023

Purchasing software and supply chain management software are often mistaken for one another, but both have distinct functionalities. While purchasing software automates the procurement process, supply chain management software executes logistical transactions and manages supplier relationships. This report identifies the similarities and differences between the two software categories to help you understand which one is better suited to your needs.

What is purchasing software?

Purchasing software is an online tool that allows businesses to automate the process of procuring goods and services. It includes security compliance and reporting features.

Purchasing solutions offer integrated tools for invoice approval, inventory control, asset management, customer service, and work order management. They help manage contracts, analyze spending, track sales deliveries, and monitor inventory levels. They also assist in identifying bottlenecks in the purchase process, such as functions that have high expenditure.

Purchasing software offers invoice processing capabilities as well. Procurement professionals and accounting teams can use the tool to generate invoices, track invoice status, and monitor expenses via detailed reports.

What is supply chain management software?

Supply chain management software is a software platform that allows supply chain managers to automate the entire supply chain process—from acquiring raw materials to delivering the finished goods to consumers. The software provides tools for monitoring stock levels, including raw materials, and predicting future requirements based on the current inflow and outflow of inventory.

Supply chain management tools manage material handling, order fulfillment, and information tracking for stakeholders such as manufacturers, suppliers, and transport and logistics providers. They also track the returns of damaged goods, process refunds and insurance claims, and provide planning and forecasting tools for supply chain professionals.

What do they have in common?

Purchasing is a crucial component of supply chain management. Together, these processes significantly contribute to an organization’s procurement cycle. Despite the functionality differences, both the software categories have a few features in common, including supplier management, order management, and forecasting.

Which tool is right for you?

The answer to this question depends on your use case. If you’re looking for a tool that majorly focuses on acquiring supplies, opt for a purchasing software solution, as it will help you streamline the procurement cycle, maintain purchase order accuracy, and monitor supplier activities. However, if you wish to manage your entire supply chain operations, including supplier, transportation, warehouse, and inventory management, then investing in a supply chain software solution would be the right choice.

Read More

Management

Article | June 21, 2023

Automated supply chain planning maximizes efficiency and helps achieve long-term success by addressing challenges, highlighting the benefits, and offering insights to optimize business performance.

Contents

1 Supply Chain Planning System Efficiency Maximization

2 Key Steps of Supply Chain Planning to Boost Efficiency

2.1 Implement Advanced Analytics Tools

2.2 Streamline Communication and Collaboration

2.3 Automate Processes

2.4 Consistency in Performance Improvement

3 Overcoming Major Challenges in the Process to Maximize Efficiency

3.1 Resistance to Change

3.2 Legacy Systems and Siloed Data

3.3 Inadequate Funding

4 Conclusion

1 Supply Chain Planning System Efficiency Maximization

To compete and succeed in an ongoing complex and dynamic global market, companies must maximize the efficiency of their supply chain planning systems, which help manage the flow of goods and services from suppliers to customers, optimize resources and information to meet customer demands and minimize costs and risks. An adequate supply chain planning system can increase customer satisfaction, profitability, agility, and risk management. Moreover, by reducing costs, increasing productivity, and enhancing responsiveness to market demands, maximizing efficiency can help businesses remain competitive. As a result, businesses can gain a substantial competitive edge and position the organization for long-term success by optimizing their supply chain planning systems.

2 Key Steps of Supply Chain Planning to Boost Efficiency

Businesses can significantly boost efficiency in their supply chain planning by implementing advanced analytics tools, streamlining communication and collaboration, automating processes, and ensuring consistency in performance improvement.

2.1 Implement Advanced Analytics Tools

Implementing advanced analytics in supply chain planning is key to improve supply chain efficiency. Advanced analytics tools, including demand forecasting, production planning and inventory management, can help organizations leverage large volumes of data to extract insights that enable better decision-making. The insights can be used to optimize production planning, reducing costs and increasing efficiency. In addition, it also enables businesses to detect and respond to supply chain disruptions on operations.

2.2 Streamline Communication and Collaboration

Managing and streamlining communication becomes essential for supply chain businesses, as it leads to greater agility and enables pipelines to adapt to changes in organizational structures. Leveraging cloud-based communication platforms, video conferencing, and collaboration tools enable real-time information sharing and collaboration across different teams and stakeholders. By enhancing communication and collaboration, businesses can better align their supply chain objectives, reduce communication gaps, and enhance decision-making.

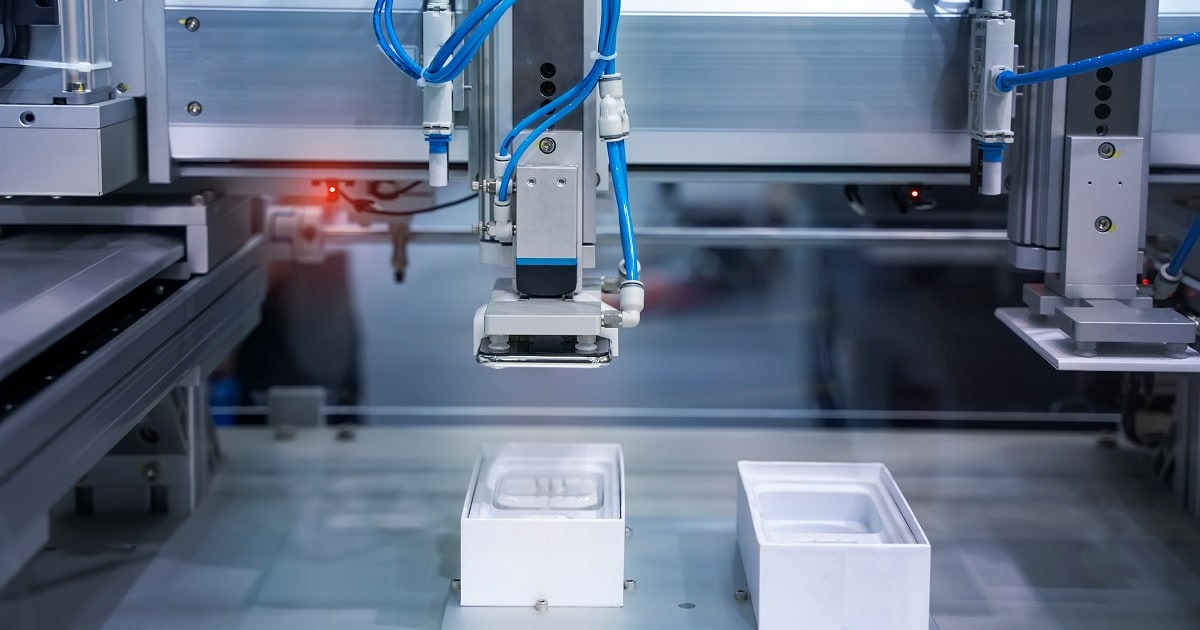

2.3 Automate Processes

The integration of technologies such as order processing, inventory management, and shipment tracking under warehouse automation and logistics automation produces a vast amount of data, making it challenging for businesses to process data manually. To enhance efficiency, automating supply chain planning processes has become essential. Automating the process has eliminated multitasking, including managing goods flow, tracking road progress, and ensuring safe delivery, which was previously required in the manual process. By automating processes, supply chain management can be streamlined, leading to reduced lead times, minimized costs, and improved efficiency.

2.4 Consistency in Performance Improvement

Improving the supply chain is not a one-time fix, but a process that must be reviewed and optimized frequently. By implementing technology, businesses can continuously collect and analyze warehouse inventory management performance to identify areas for further efficiency gains and improved order accuracy. In addition, establishing a framework for continuous optimization involves regular performance reviews, feedback mechanisms, and benchmarking against industry best practices to help identify and address inefficiencies.

3 Overcoming Major Challenges in the Process to Maximize Efficiency

3.1 Resistance to Change

Supply chain planning systems are hindered by change resistance. Employees may resist change who are comfortable with the status quo and adopt new technologies and processes less often. Organizations need a comprehensive change management plan to address stakeholder engagement, communication, and training. Implementing a change management plan starts with identifying the key stakeholders and involving them in planning to gain their buy-in and support for the changes, implementing the process of the changes using different channels to reach all stakeholders and in addition, developing training programs to prepare employees for the changes and enable them to use new technologies and processes effectively.

3.2 Legacy Systems and Silos Data

Data silos and a lack of supply chain visibility are two problems that can arise when legacy systems and data are used. It also adds roadblocks in maximizing efficiency through supply chain planning software. Investing in older systems makes it challenging to gain a comprehensive view of the supply chain and informed decisions making. In addition, the systems are non-compatible with modern technology and data is stored in disconnected systems. With the help of an integrated system, all relevant information can be collected in one place, streamlining monitoring and decision-making. A data governance policy should be implemented to guarantee data quality and uniformity across all platforms. Data management, data storage, data sharing, regular monitoring and reporting on data quality are all essential components of this policy.

3.3 Inadequate Funding

Insufficient funding can affect supply chain planning system efficiency; with budget constraints, organizations may struggle to invest in new technologies, hire skilled workers, or improve processes. Thus, the supply chain planning system may become obsolete, increasing costs, lead times, and customer dissatisfaction. To overcome the challenge of inadequate funding in supply chain planning, organizations must prioritize funding and strategically allocate resources by identifying the areas that require the most investment. Exploring alternative funding sources, such as grants and partnerships, can supplement existing funding and enable organizations to invest in vital initiatives that may not have been possible with limited resources. In addition, cost-cutting measures, such as process optimization and automation, can help to stretch existing funds and boost productivity.

4 Conclusion

The supply chain planning system will continue to play a critical role in maximizing efficiency to revolutionize the supply chain professionals leverage emerging technologies such as AI, ML, and blockchain; understanding the process, identifying the challenges and overcoming them using the right strategies helps businesses in effective supply chain planning systems, gain a competitive advantage, improve supply chain performance and position themselves for long-term success. Furthermore, adopting a data-driven approach and a culture of continuous improvement in supply chain management planning can help organizations plan according to the future of supply chain and compete in the ever-changing global market.

Read More

Supply Chain

Article | August 17, 2023

Autonomous robots have transitioned from a futuristic system that only a few enterprises could afford to a sustainable, well-established solution in a wide assortment of warehouse automation projects in recent years.

With the flourishing transportation and logistics industry and increasing e-commerce penetration worldwide, innovative technologies are revealing promising opportunities throughout the supply chain.

Warehouse Automation: Driving Value in the Supply Chain

Historically, autonomous robots have been used to perform tedious and repetitive tasks, necessitating sophisticated programming for setup and incorporation while lacking the dexterity to easily adjust operations.

As autonomous robots become more intelligent, their setup times decrease, they need less monitoring, and they are able to work alongside their human counterparts. The benefits for the future supply chain are increasing as autonomous robots become more capable of working day and night with more consistent levels of productivity and quality and performing tasks that individuals should not, cannot, or do not want to do.

Autonomous robots drive advancements and add value to the supply chain, primarily by increasing revenue potential and lowering direct and indirect operating costs. Autonomous robots, in particular, can assist:

Boost efficiency and productivity.

Lower risk, error frequency, and rework rates.

Enhance employee safety in high-risk workplaces.

Handle low-value, routine tasks so people can work together on strategic projects that can't be done by machines.

Raise revenue by optimizing order fulfillment rates, and delivery speed, and, ultimately, increasing customer satisfaction.

Sneak Peek into the Future of Autonomous Robot

Autonomous robots are expected to witness strong growth in the coming years. These robots will become more common in the future supply chain as technology advances, allowing them to operate with more human-like abilities. Improvements in haptic sensors, for example, will enable these robots to grasp objects varying from multi-surfaced metal assembly parts to fragile eggshells without requiring changes to robotic components or programming. This will encourage companies operating in the industry to increase their research and development activities and introduce innovative and advanced supply chain technologies.

Read More

Article | October 19, 2020

Warehouse logistics is the heart of any supply chain operation, assimilating and dispatching goods to ensure availability and timely delivery. With more consumers turning to e-commerce, it’s important for businesses of all sizes to bolster the supply chain to handle the e-commerce business model. According to research conducted by BigCommerce, the top three factors that influence consumers’ online purchasing decisions are convenience, cost and free shipping. In fact, the National Retail Federation (NRF) found that 75% of consumers expect delivery to be free even for orders under $50.

Read More