Warehousing and Distribution

Article | July 11, 2023

Explore the techniques to improve warehousing and distribution centre. Learn from the best books of logistics and distribution management and enhance warehousing operations and distribution processes.

Efficient warehouse management is crucial in the complex world of distribution and logistics. With various warehouse types serving different purposes, warehouse managers are responsible for ensuring smooth operations, safeguarding valuable goods, and optimizing supply chain units. Building a strong knowledge base is key, and the best way to start is by delving into the top warehouse management books. This article presents a curated list of essential reads that will provide you with a solid foundation in the warehouse and distribution field. From understanding fundamentals to exploring cutting-edge practices, these books help in better decision-making regarding warehousing and distribution operations.

1. Fundamentals of Warehousing & Distribution

Author Name: Material Handling Industry

Fundamentals of Warehousing & Distribution is an essential book for professionals in the warehousing and distribution industry. Published as part of the MHI Career & Technical Education Program, this series of four warehouse management books provides comprehensive knowledge on material handling equipment, information technology tools, and warehouse operations. Volume 1 serves as a foundational guide, introducing readers to modern warehouses and distribution centers' equipment, processes, and operations. With its focus on practical knowledge and industry best practices, this warehouse and distribution book provides readers with the skills and expertise necessary for successful warehouse and distribution management.

2. Warehousing and Distribution Practices

Author Name: xu ji ying

Divided into two parts, Warehousing and Distribution Practices covers seven key areas of the real-world processes for managing storage and implementation of effective distribution strategies. This distribution management book focus on essential knowledge and skills, each section provides valuable insights through logistics standard terms, case studies, knowledge links, and practical application. As one of the best books on logistics and distribution management, it will give you the complete step-by-step guidance to expand and improve warehousing and distribution centre by leveraging the theory shared by xu ji ying.

3. Warehousing And Distribution Management Project Type Tutorial

Author Name: Wang Yu

Warehousing and Distribution Management Project Type Tutorial, a logistics and supply chain management book, revolutionize logistics education with its innovative approach. This comprehensive book goes beyond traditional teaching methods, immersing readers in real-world scenarios and practical projects. Through eleven immersive teaching projects and thirty-two dynamic learning tasks, readers gain hands-on experience in system planning, business management, quality control, inventory operations, technology application, and more. Developed in collaboration with industry experts, this tutorial bridges the gap between theory and practice, empowering logistics professionals to navigate the complexities of warehouse and distribution management. With its unique project-based structure, this warehousing and distribution book delivers a transformative learning experience for aspiring logistics and supply chain industry leaders.

4. Fundamentals of Warehousing & Distribution: Volume 3

Author Name: MHI

Fundamentals of Warehousing & Distribution, a logistics and supply chain management book revolutionizes how logistics professionals perceive warehouses. By delving into captivating case study examples, this book unveils the intricacies of different warehouse configurations, showcasing how cutting-edge equipment and technologies empower diverse order fulfilment strategies. It challenges conventional wisdom by emphasizing that warehouses are no longer mere storage spaces; they have transformed into dynamic hubs that efficiently cater to a wide range of order types, from bulk shipments to individual products. With its ground-breaking insights and practical applications, this volume is a game-changer for industry experts seeking to elevate their warehousing and distribution management skills.

5. Warehouse Distribution and Operations Handbook

Author Name: David Mulcahy

Optimize warehouse operations with this warehouse and distribution management book, Warehouse Distribution and Operations Handbook. With a focus on improving inventory management, reducing costs and enhancing customer experiences, this handbook offers best practices, methods, equipment applications and technologies to utilize in different warehouse and distribution centres. Whether it's industrial, mail-order, or retail facilities, this comprehensive logistics and distribution management book provides the knowledge and strategies to drive profitability and control assets. It is an essential resource for anyone in the logistics industry looking to master distribution management and excel in warehouse operations.

6. Warehouse and Distribution Centre

Author and Editor Name: Robert Mulder & Michiel Kobussen

The warehouse and Distribution Centre is a valuable resource for logistics professionals and architects navigating the evolving landscape of warehouse design. This distribution management book addresses designers' pressing challenges, including cost control, technical requirements, and safety considerations. It offers a comprehensive system of theories, guidelines, and design standards, accompanied by a diverse collection of global warehouse and distribution centre projects. Balancing both the ends of practical reference and inspirational examples, this best book for distribution management equips readers with the knowledge and insights needed to create efficient, innovative, and sustainable warehouse and distribution solutions. It is a must-read for anyone involved in warehousing and distribution management.

7. Warehousing and Distribution Operation Practice

Author Name: peng jian cheng

Rooted in practical vocational education, Warehousing and Distribution Operation Practice is a book that emphasizes integrating theoretical knowledge with functional operations. It provides a hands-on approach to learning, enabling readers to apply their knowledge directly in real-world scenarios. This warehousing and distribution book will give you the required skills and expertise to optimize operational efficiency. With the help of practices shared by peng jian in the warehouse management book, readers will get insights into supply chain management and logistics operations. In addition, it will not only help in improving the processes in the warehouse and distribution but also enhance the overall business.

8. Operations and Supply Chain Management Essentials You Always Wanted to Know

Author Name: Vibrant Publishers & Ashley McDonough

Overcome the complexities of supply chain management and warehouse operations with Operations and Supply Chain Management Essentials You Always Wanted to Know. This engaging book takes you on a captivating journey through the interconnected world of logistics, unveiling the significance of every step in the process. Through a compelling narrative centred around a fictional company and its consumer product, you'll explore the challenges, decisions, and adaptations supply chain professionals face. Gain a deep understanding of supply chain operations, from disruptive forces to practical applications, and discover the importance of interactive business domains.

9. Start your Own Wholesale Distribution Business

Author Name: The Staff of Entrepreneur Media & Christopher Matthew Spencer

Embark on a lucrative journey in the distribution industry with 'Start Your Own Wholesale Distribution Business.' This comprehensive guide, crafted by the experts at Entrepreneur Media, equips you with the essential steps to establish a thriving wholesale operation from the comfort of your home. Discover the art of being an intermediary, connecting manufacturers and retailers to reap profits. Uncover industry-specific strategies, secure funding, identify profitable niches, forge valuable partnerships, and effectively market your business. With insights from experienced wholesale distributors, sample forms, checklists, and worksheets, this warehousing and distribution book is your roadmap to mastering the world of distribution and logistics.

10. Warehouse Management: The Definitive Guide to Improving Efficiency and Minimizing Costs in the Morden Warehouse

Author Name: Gwynne Richards

Discover one of the best books for logistics management in the modern era with 'Warehouse Management: The Definitive Guide to Improving Efficiency and Minimizing Costs in the Modern Warehouse.' This extensively updated fourth edition delves into the latest technologies, such as robotics, cobots, and AI, revolutionizing warehouse operations. Author Gwynne Richards offers expert insights and realistic solutions to optimize warehouse performance and improve efficiency. This effective distribution management book provides strategies and environmental initiatives to ensure a sustainable supply chain. Packed with real case studies and online resources, this book is an essential resource for distribution and logistics professionals.

Conclusion

Warehousing and distribution books have been a valuable resource for reference in the logistics field. While this compilation is not exhaustive, it offers a robust selection of warehouse management books that can effectively address various related challenges. Whether seeking insights into warehouse and transportation management or exploring other facets of supply chain management, logistics management, and procurement, the knowledge gained will be a worthwhile investment for future decision-making.

Read More

Management

Article | June 21, 2023

Maintain a competitive advantage by effectively managing supply chain. Discover the potential opportunities and enhance the career in logistics with warehousing and distribution certificates.

The rapidly changing and fiercely competitive business landscape necessitates that professionals must go an extra mile to maintain a leading edge and propel their careers forward. Taking the initiative to pursue warehousing and logistics certifications can significantly boost your career. By obtaining a recognized designation, you demonstrate a steadfast dedication to your profession, enhancing your appeal to potential employers. Furthermore, earning a respected certification can open doors to advancement opportunities and increase making potential within your current organization. Moreover, pursuing ongoing education offers rewards, keeping you engaged and ensuring you remain at the forefront of industry developments.

1. Supply Chain Warehousing Certificate

Supply Chain Warehousing Certificate is a comprehensive program for individuals seeking expertise in warehousing and logistics. Developed by ASCM and Prologis, it covers essential topics such as inventory management, packaging, shipping, and sustainability in logistics. This self-paced course offers flexibility and can be accessed on mobile devices. Earning one of the exclusive warehousing and distribution certifications demonstrates your knowledge and expertise in managing inventory and helps you stand out in the competitive job market. Employers will recognize your ability to handle shipping processes, improve order fulfilment, and make informed transportation decisions.

2. SAP Extended Warehouse Management Training

Enhance your expertise in warehousing management with this top-tier online certification course. Gain in-depth knowledge of extended warehouse management, including warehousing structures, expert data, and warehouse organization. This warehousing and distribution course includes techniques for processing received and shipping goods, slotting, replenishment methods, and physical inventory. Delivered through video and text-based modules, it provides comprehensive warehousing and distribution center operations training. In addition, this course will expand your career opportunities and help you excel in the dynamic field of warehousing management.

3. Storage and Distribution Certification

Storage and Distribution Certification is a complete course that addresses the critical need for supply chain safety and integrity in today's complex logistics landscape. This supply chain warehousing certificate is focused on distribution and is designed for warehousing, logistics, and supply chain management professionals. The program covers supply chain visibility, risk management, and optimizing physical-flow networks. There are no specific eligibility criteria for this course, making it accessible to a wide range of individuals seeking to enhance their skills and knowledge. By obtaining this one amongst many warehousing certifications in this course , you'll be equipped with the expertise to mitigate supply chain vulnerabilities, improve operational resilience, and meet the evolving demands of the modern marketplace.

4. Certified International Warehouse and Inventory Manager

The Certified International Warehouse & Inventory Manager certification offered by Blue Ocean Academy in Dubai and Abu Dhabi provides professionals with comprehensive training in warehouse management. Blue Ocean Academy, recognized as an industry leader in this field, offers the best warehouse and inventory management training courses. The Warehouse Management Certification Program focuses on the strategic role of warehousing within the broader context of supply chain management and logistics. Participants will gain knowledge and skills in the latest methods for storing and safeguarding high-value inventories and best practices for modern warehousing. The program also covers techniques to achieve accurate record-keeping and successful cycle counting, methods for conducting warehouse audits, and the operational and financial performance aspects of warehousing.

5. Warehouse Excellence Certification (WAREX)

Developed by the Institute of Supply Chain Management (IoSCM), Warehouse Excellence Certification (WAREX) helps to elevate your warehousing career. This logistics warehousing and distribution program offers a range of qualifications catering to professionals at various stages of their logistics, warehousing, and distribution journeys. WAREX covers a broad spectrum of skills and knowledge, from entry-level to strategic management positions. Whether you're new to the industry or a seasoned professional, this certification equips you with the expertise to optimize warehouse operations, enhance inventory management, and drive overall supply chain efficiency.

6. Six Sigma Certification in Warehousing: Overview & Career Options

Six Sigma Certification in warehousing is a specialized program that equips professionals with the tools and methodologies to optimize warehouse operations, eliminate defects, and achieve near-perfect efficiency levels of 99.997%. By applying Six Sigma processes, businesses can identify and solve warehouse problems, resulting in improved customer satisfaction, increased revenue, reduced errors, efficient inventory management, and enhanced overall profitability. With this warehouse certification program, you'll stand out in the job market with higher employability, salary potential, and opportunities with renowned companies like Amazon, Samsung, Boeing, FedEx, DHL, and UPS.

7. Certified International Warehouse & Inventory Manager

This certificate in warehousing management is specifically designed to equip professionals with the necessary skills and knowledge to excel in the dynamic world of warehouse operations. This program covers a wide range of essential topics, from strategic warehouse management to inventory optimization and sustainable practices. Participants will learn about warehouse design, storage techniques, materials handling, inventory control, performance measurement, warehouse management systems, risk management, and sustainability. This warehousing and logistics certification is ideal for warehouse managers, logistics professionals, supply chain executives, and individuals seeking to enhance their expertise in warehouse operations.

8. WHSEOPSCERT - Warehouse Operations Certificate

The Warehouse Operations Certificate program offers essential training to develop fundamental warehousing skills and gain certifications in material handling equipment. This program is crafted to enhance participants' employability within the warehousing and distribution industries. It covers various topics, including warehouse operations, supply chain fundamentals, order fulfillment, shipping concepts, and lift truck certification training. The courses provide a comprehensive understanding of warehouse functions, inventory management, storage procedures, supply chain principles, and problem-solving strategies. Upon completion, graduates will be equipped for entry-level positions such as Order Puller, Warehouse Technician, Logistics Analyst, and more.

9. JHSC Certification Part Two - Warehousing & Distribution

The JHSC Certification Part Two - Warehousing & Distribution is an essential training program designed to equip participants with the knowledge and skills to recognize and control hazards within their warehousing and distribution workplaces. After completing both Part One and Part Two training, this certification is the final step in becoming a certified member of a Joint Health and Safety Committee (JHSC). Aligned with the Ministry of Labour's JHSC Certification Training Program Standard, this interactive 2-day course strengthens participants' understanding of the RACE process (Recognition, Assessment, Control, and Evaluation) for all workplace hazards. Delivered by experienced health and safety experts familiar with the industry, this training covers sector-specific risks such as MSDs, slips and falls, motor vehicle incidents, unguarded machinery, unsafe material handling, and hazardous chemicals. Completing this certification ensures compliance with legal requirements, empowers individuals to make informed decisions regarding workplace safety, and enhances overall hazard management in the warehousing and distribution sector.

10. Warehouse Distribution, Continuing Education Workforce Certificate

Warehouse Distribution Continuing Education Workforce Certificate is a comprehensive training program to equip individuals with the necessary skills for higher-skilled, frontline material handling roles within the supply chain industry. Ideal for individuals seeking employment in various supply chain facilities, such as warehouses, distribution centers, and transporters, this program prepares students for different job positions, including forklift operators, logistics specialists, freight handlers, and customer support representatives. By completing this certificate, learners will not only gain essential knowledge in waste reduction, logistics security, and forklift safety, but they will also have the opportunity to obtain the Certified Logistics Associate (CLA) credential from the Manufacturing Skill Standards Council (MSSC) and other relevant certificates. This certification provides a concrete foundation for entry-level careers in the logistics field and offers individuals a competitive edge in the job market.

Conclusion

Logistics and supply chain management professionals thrive on the exhilarating pace of constant change. Each day brings fresh challenges, opportunities, and innovative tools that enhance tracking, analysis, forecasting, and more. By actively pursuing a logistics or supply chain certification and diligently fulfilling the required continuing education hours, ensure that you remain at the forefront of these exciting industry advancements. This commitment positions you to leverage the latest insights and technologies, allowing you to optimize and streamline your supply chains for maximum efficiency. As a result, you stay ahead of the curve and empower your organization to achieve peak performance and drive continued success. Embrace the transformative power of certifications and embark on a journey of growth and excellence in logistics and supply chain management.

Read More

Supply Chain

Article | August 17, 2023

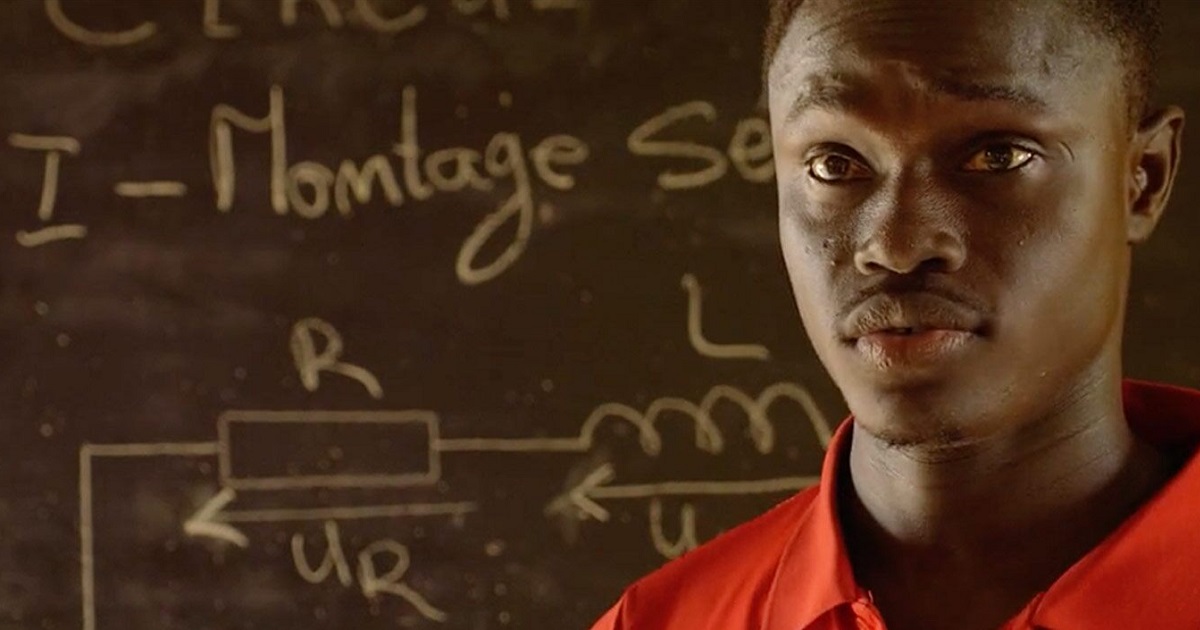

With half a million people benefited in 60+ countries, the Tomorrow Rising Fund is now focusing on education and professional training programs to secure the best future for young people and their communities affected by COVID-19.

Two months after launching the Tomorrow Rising fund to support Covid-19 emergency relief in April 2020, Schneider Electric’s Foundation moves forward to support recovery and resiliency through education and training programs.

The Tomorrow Rising Fund was launched to support emergency and longer-term reconstruction related to Covid-19 in all the countries where Schneider Electric operates. The Schneider Electric Foundation appealed to its leaders and employees to get involved and all their donations have been matched by the Group. Other external stakeholders and partners have also contributed.

Read More

Supply Chain

Article | April 26, 2023

Automated supply chain planning maximizes efficiency and helps achieve long-term success by addressing challenges, highlighting the benefits, and offering insights to optimize business performance.

Contents

1 Supply Chain Planning System Efficiency Maximization

2 Key Steps of Supply Chain Planning to Boost Efficiency

2.1 Implement Advanced Analytics Tools

2.2 Streamline Communication and Collaboration

2.3 Automate Processes

2.4 Consistency in Performance Improvement

3 Overcoming Major Challenges in the Process to Maximize Efficiency

3.1 Resistance to Change

3.2 Legacy Systems and Siloed Data

3.3 Inadequate Funding

4 Conclusion

1 Supply Chain Planning System Efficiency Maximization

To compete and succeed in an ongoing complex and dynamic global market, companies must maximize the efficiency of their supply chain planning systems, which help manage the flow of goods and services from suppliers to customers, optimize resources and information to meet customer demands and minimize costs and risks. An adequate supply chain planning system can increase customer satisfaction, profitability, agility, and risk management. Moreover, by reducing costs, increasing productivity, and enhancing responsiveness to market demands, maximizing efficiency can help businesses remain competitive. As a result, businesses can gain a substantial competitive edge and position the organization for long-term success by optimizing their supply chain planning systems.

2 Key Steps of Supply Chain Planning to Boost Efficiency

Businesses can significantly boost efficiency in their supply chain planning by implementing advanced analytics tools, streamlining communication and collaboration, automating processes, and ensuring consistency in performance improvement.

2.1 Implement Advanced Analytics Tools

Implementing advanced analytics in supply chain planning is key to improve supply chain efficiency. Advanced analytics tools, including demand forecasting, production planning and inventory management, can help organizations leverage large volumes of data to extract insights that enable better decision-making. The insights can be used to optimize production planning, reducing costs and increasing efficiency. In addition, it also enables businesses to detect and respond to supply chain disruptions on operations.

2.2 Streamline Communication and Collaboration

Managing and streamlining communication becomes essential for supply chain businesses, as it leads to greater agility and enables pipelines to adapt to changes in organizational structures. Leveraging cloud-based communication platforms, video conferencing, and collaboration tools enable real-time information sharing and collaboration across different teams and stakeholders. By enhancing communication and collaboration, businesses can better align their supply chain objectives, reduce communication gaps, and enhance decision-making.

2.3 Automate Processes

The integration of technologies such as order processing, inventory management, and shipment tracking under warehouse automation and logistics automation produces a vast amount of data, making it challenging for businesses to process data manually. To enhance efficiency, automating supply chain planning processes has become essential. Automating the process has eliminated multitasking, including managing goods flow, tracking road progress, and ensuring safe delivery, which was previously required in the manual process. By automating processes, supply chain management can be streamlined, leading to reduced lead times, minimized costs, and improved efficiency.

2.4 Consistency in Performance Improvement

Improving the supply chain is not a one-time fix, but a process that must be reviewed and optimized frequently. By implementing technology, businesses can continuously collect and analyze warehouse inventory management performance to identify areas for further efficiency gains and improved order accuracy. In addition, establishing a framework for continuous optimization involves regular performance reviews, feedback mechanisms, and benchmarking against industry best practices to help identify and address inefficiencies.

3 Overcoming Major Challenges in the Process to Maximize Efficiency

3.1 Resistance to Change

Supply chain planning systems are hindered by change resistance. Employees may resist change who are comfortable with the status quo and adopt new technologies and processes less often. Organizations need a comprehensive change management plan to address stakeholder engagement, communication, and training. Implementing a change management plan starts with identifying the key stakeholders and involving them in planning to gain their buy-in and support for the changes, implementing the process of the changes using different channels to reach all stakeholders and in addition, developing training programs to prepare employees for the changes and enable them to use new technologies and processes effectively.

3.2 Legacy Systems and Silos Data

Data silos and a lack of supply chain visibility are two problems that can arise when legacy systems and data are used. It also adds roadblocks in maximizing efficiency through supply chain planning software. Investing in older systems makes it challenging to gain a comprehensive view of the supply chain and informed decisions making. In addition, the systems are non-compatible with modern technology and data is stored in disconnected systems. With the help of an integrated system, all relevant information can be collected in one place, streamlining monitoring and decision-making. A data governance policy should be implemented to guarantee data quality and uniformity across all platforms. Data management, data storage, data sharing, regular monitoring and reporting on data quality are all essential components of this policy.

3.3 Inadequate Funding

Insufficient funding can affect supply chain planning system efficiency; with budget constraints, organizations may struggle to invest in new technologies, hire skilled workers, or improve processes. Thus, the supply chain planning system may become obsolete, increasing costs, lead times, and customer dissatisfaction. To overcome the challenge of inadequate funding in supply chain planning, organizations must prioritize funding and strategically allocate resources by identifying the areas that require the most investment. Exploring alternative funding sources, such as grants and partnerships, can supplement existing funding and enable organizations to invest in vital initiatives that may not have been possible with limited resources. In addition, cost-cutting measures, such as process optimization and automation, can help to stretch existing funds and boost productivity.

4 Conclusion

The supply chain planning system will continue to play a critical role in maximizing efficiency to revolutionize the supply chain professionals leverage emerging technologies such as AI, ML, and blockchain; understanding the process, identifying the challenges and overcoming them using the right strategies helps businesses in effective supply chain planning systems, gain a competitive advantage, improve supply chain performance and position themselves for long-term success. Furthermore, adopting a data-driven approach and a culture of continuous improvement in supply chain management planning can help organizations plan according to the future of supply chain and compete in the ever-changing global market.

Read More