Improve supply chain operations with innovative inventory management best practices. Uncover the techniques for achieving exceptional supply chain performance in the B2B competitive marketplace.

Effective inventory management is critical for businesses seeking to optimize their supply chain operations and improve their warehousing & supply chain distribution efficiency. By employing demand optimization techniques, inventory management aims to strike the right balance between meeting current and anticipated future demand while minimizing unnecessary inventory costs. Organizations that maintain optimal inventory levels can mitigate challenges associated with inventory, such as overstocking and stockouts.

In supply chain management, inventory optimization is vital, as it directly impacts organization’s ability to thrive. For any enterprise selling products, the effective management of goods is essential. Without adequate stock levels for sales or fulfilling customer orders, revenue generation and overall income can be severely hindered. Inefficient inventory management, leading to stock shortages, can create stumbling blocks for businesses. Conversely, improper stock tracking resulting in excess inventory can strain financial resources. As these issues compound, it further contributes to inventory imbalances, eventually leading to bottom-line losses from expired or redundant stock.

According to a recent Statista survey, 40% of the supply chain industry has already adopted advanced technologies to optimize its inventory and using networking tools.

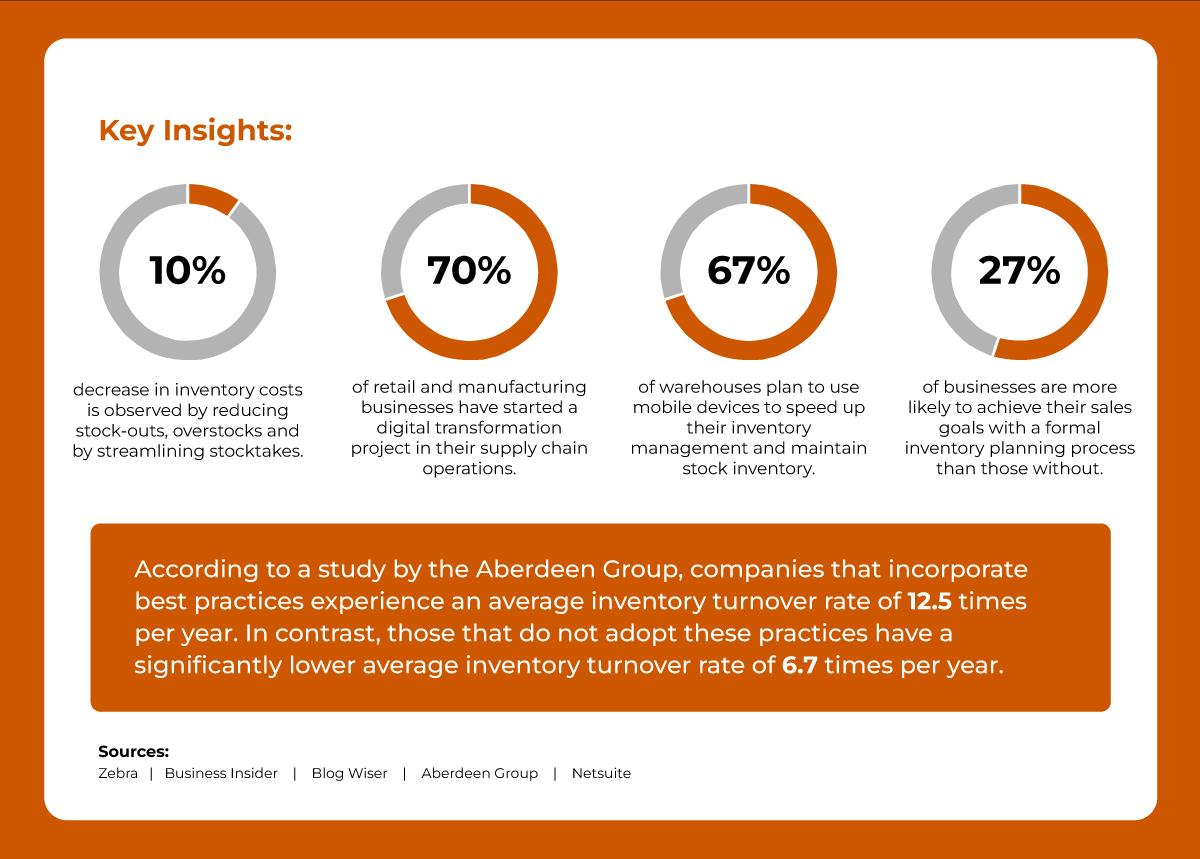

The above data signifies the importance of optimizing and managing inventory for improved supply chain performance. Inventory analytics, typically overseen by an inventory manager, offer valuable insights that aid in understanding and enhancing inventory performance. Inventory management best practices help achieve effective inventory optimization, crucial data points encompassing products, suppliers, procurement, purchases, and sales that are meticulously tracked within the inventory management system. These data, in turn, serve as the foundation for formulating inventory metrics aimed at demand optimization.

This article explains the techniques to optimize and manage inventory with the inventory management best practices that helps overcoming challenges, addressing procedural considerations, and highlighting the significance of implementing these methods. Additionally, it explores the benefits of adopting solution for improved supply chain distribution network.

1. Implementing Standard Inventory Review Systems

To enhance

supply chain operations, adopting standard inventory review system is essential, which can significantly contribute to inventory optimization efforts. Two effective methods to review systems include the continuous review system and periodic review system. In the continuous review system, fixed quantities of items are ordered in each cycle, providing a steady and consistent approach to inventory management.

On the other hand, the periodic review system involves collecting products at predetermined intervals, considering the inventory levels at that specific moment. Embracing these standardized review systems empowers businesses to streamline inventory processes, maintain optimal stock levels, and improve overall supply chain efficiency.

2. Streamline Stocktake

Supply chain operations can be improved by streamlining the stocktaking process, which involves meticulously counting and managing inventory. A well-structured stocktake procedure ensures accuracy and prevents losses by keeping staff engaged and focused.

To achieve accuracy and earn profits, businesses must:

-

Schedule stocktakes strategically to minimize disruption in regular business operations.

-

Prioritize cleaning and organizing the stockroom before the stocktake to facilitate efficient counting.

-

Clearly define the item count and the counting methods to eliminate guesswork.

-

Conduct comprehensive stock counts, leaving no room for assumptions.

By implementing these measures, businesses can optimize inventory management, identify discrepancies promptly, and maintain precise stock records. The streamlined stocktake process contributes to smoother supply chain operations, reduces inventory-related errors, and enhances overall productivity and profitability.

3. Utilize Cloud-Based Inventory Management System

Transitioning from Excel inventory management to a cloud-based inventory management system is critical to enhancing supply chain operations. It is considered one of the most used inventory control best practices. Unlike locally-installed applications, cloud-based software offers numerous advantages, enabling businesses to pay for essential features and effortlessly upgrade as needs evolve. Companies can efficiently manage costs with a predictable subscription fee tailored to feature requirements and team size. Seamless upgrades become hassle-free as business growth justifies a move to a more robust platform, ensuring scalability.

Additionally, cloud technology provides continuous support, ensuring smooth operations and quick issue resolution. With a dedicated support team on standby, businesses can focus on optimizing inventory management, managing warehouse automation, and driving overall productivity. Embracing cloud-based inventory management is a business-changing decision that unlocks increased agility, accessibility, and cost-effectiveness for long-term success.

4. Implement Adequate Quality Control Practices

Enhancing supply chain operations requires the implementation of robust quality control practices. Accurate quality control processes play a pivotal role in maintaining inventory quality, directly impacting customer satisfaction and business growth.

Effective steps include developing comprehensive checklists, outlining stock-taking procedures, followed by standard operating procedures to qualify or disqualify products with effective warehouse management systems. By adhering to these protocols, businesses can prevent issues of overstocking or understocking, ensuring customers receive only appropriate merchandise.

Companies can strengthen their reputation, increase operational efficiency, and cultivate lasting customer loyalty through this inventory optimization best practice. The seamless integration of quality control practices into the supply chain fosters a thriving business environment built on excellence and customer-centricity.

5. Preparing Well Planned Inventory Budget

A well-structured inventory budget is one of the industry-used inventory management best practices to enhance logistics distribution and supply chain processes. Managers commonly utilize an annual inventory budget, meticulously prepared before procuring inventory. The budget is designed to encompass the total cost of ownership for the upcoming accounting period, encompassing materials cost, fixed operational expenses, transportation and logistics charges, redistribution costs, and other miscellaneous expenses impacting the inventory's total cost of ownership. By crafting a comprehensive inventory budget, businesses gain financial clarity, optimize resource allocation, and ensure efficient inventory management throughout the year. A well-planned budget empowers informed decision-making, minimizing financial risks and driving overall supply chain success.

6. Carrying Safety Stock Inventory

Operations in the supply chain require safety stock inventory – a strategically maintained surplus of inventory to protect against market demand and lead time fluctuations. By implementing safety stock, businesses can avoid revenue loss, customer attrition, and declining market share that may arise in its absence.

Safety stock is vital with the advantages it offers:

-

Protection against sudden surges in demand.

-

Prevention of stockouts, ensuring uninterrupted customer service.

-

Compensation for inaccuracies in market forecasts.

-

A buffer for longer-than-expected lead times, averting production delays.

Incorporating safety stock as a fundamental inventory management best practice empowers companies to achieve operational supply chain resilience, optimize customer satisfaction, and maintain a competitive edge in the dynamic market landscape.

7. Optimize Inventory Turnover Rates

Optimizing inventory turnover rates is a critical metric that frequently measures inventory sold or used within a specific timeframe, typically a year. Calculating turnover rates provides valuable insights into market demand, identifies obsolete stock, and guides inventory management decisions.

Inventory turnover can be improved through various strategies, such as experimenting with pricing to attract more customers and boost sales, liquidating obsolete stock to free up capital and storage space, forecasting customer demand accurately to maintain optimal inventory levels, and redistributing inventory among warehouses for better stock availability. By optimizing inventory turnover rates, businesses can reduce carrying costs, minimize stock obsolescence, and enhance overall supply chain efficiency, as well as gaining competitive advantage in the market.

“It’s been my observation that the business world has a weak understanding of inventory management and control. They are trained shallowly, and sometimes they apply only shallow experience to their practices. Sometimes, that works out great. In my 30 years of experience, however, I have seen that a lot of money can be saved by training and managing inventory control in-depth.”

-Inventory Control Expert Dr. Pyke

Final Thoughts

Adopting advanced inventory management best practices is crucial for supply chain optimization in the competitive B2B environment. Standardized inventory review systems and streamlined stocktakes optimize control and accuracy, minimizing disruptions. Cloud-based inventory management offers scalability and continuous support, facilitating data-driven decisions. Adequate quality control ensures inventory quality, driving customer loyalty. Well-planned budgets lead to financial clarity and precise resource allocation. Safety stock inventory and optimized turnover rates fortify businesses against uncertainties, boosting efficiency and profitability. By embracing these practices, logistics professionals can enhance supply chain potential, achieve lasting success, and gain a competitive advantage in the market. With a data-focused approach, these strategies pave the way for streamlined operations, stronger customer relationships, and sustained growth.