Supply Chain

Article | August 17, 2023

Transform the supply chain with cutting-edge warehouse automation tools. Enhance productivity, minimize costs, and deliver exceptional customer experiences to stay ahead in the competitive market.

In the rapidly evolving world of manufacturing, logistics, and supply chain management, adopting automation has become imperative for businesses aiming to maintain a competitive edge. By minimizing costs, enhancing efficiency, and reducing downtime, automation delivers optimal value for manufacturers. However, selecting the right partner can be challenging with numerous warehouse automation companies available. This article explains the features and benefits of top ten warehouse automation tools that offer expertise in improving business operations. These data warehouse tools provide comprehensive solutions to meet diverse needs of the logistics and warehousing companies and improve the supply chain performance.

1. 3PL WMS Software Solution

3PL WMS Software Solution is one of the leading warehouse automation tools for supply chain operations. This software has comprehensive features that automate and streamline warehouse processes, offering unprecedented efficiency. The tool seamlessly integrates with existing systems and provides total transparency and control. 3PL warehouse automation software boosts order throughput, reduces pick time, and automates billing effortlessly. Gain unprecedented insights through accurate, real-time reporting, ensuring inventory accuracy and reducing lost-inventory costs. This warehouse automation tool, designed as the warehouse management backbone, revolutionizes operations, enhances customer satisfaction, and drives exponential growth.

2. Datex 3PL WMS

Datex 3PL WMS offers the most innovative warehouse management tools that help implement warehouse automation in the supply chain process for transportation services. This software empowers transportation and logistics services, revolutionizing material handling, storage, trans-loading, cross-docking, and more. It supports diverse industries such as refineries, steel mills, and energy distribution facilities. Its flexibility makes it an optimal solution to handle any inventory type, including bulk materials, steel products, liquids, and hazardous materials. This automated warehouse software also enables multi-warehouse operations and accommodates various modes of transportation. Additionally, Datex 3PL WMS boasts a highly flexible billing system, allowing individualized billing strategies and capturing value-added services. Industry experts benefit from streamlined processes, improved efficiency, and accurate billing, ultimately enhancing their supply chain business and warehouse operations.

3. Deposco

Deposco Bright Warehouse is a game-changing warehouse management software solution that offers advanced features and capabilities to businesses of all sizes. This data warehouse tool empowers companies to pick, pack, and ship orders efficiently, optimizing processes to further improve order fulfillment while reducing operational costs. It provides strategic order allocation, workgroup segmentation, and optimized picking strategies, to achieve accurate and speedy order fulfillment. The software offers network-wide inventory visibility through advanced tracking, barcoding, and management capabilities. This solution automates shipping processes by seamlessly integrating with carriers, ensuring maximum accuracy and speed. Leveraging its material handling technology for automation can lead to significant productivity improvements. Businesses can enhance their capabilities by accessing a unified view of operations, utilizing customization options, and benefiting from direct API integration with shipping carriers.

4. Softeon

Softeon is a powerful warehouse management tools for supply chain automation. Its comprehensive WMS optimizes distribution operations, handling all essential tasks while offering unique functionality for a competitive edge. With a proven deployment success rate and flexible delivery options in the cloud or on-premise, Softeon empowers businesses to streamline inventory management and delivery processes. By integrating with their Warehouse Execution System (WES), warehouse and distribution companies can further enhance order fulfillment orchestration and optimization. Industry leaders like UPS Supply Chain Solutions and Sears Home Services rely on this warehouse automation software.

5. Logiwa WMS

Logiwa WMS offers a cloud fulfillment platform that combines WMS software and order fulfillment capabilities, enabling companies to operate a digital fulfillment network and expand their direct-to-consumer operations without the need for additional staff. The data warehouse management tool offers comprehensive warehouse and inventory management functionality, billing, and seamless integrations with over 200 ecommerce, accounting, and shipping solutions; it empowers 3PL providers to optimize order fulfillment, enhance speed and accuracy, and drive customer satisfaction.

6. SnapFulfill

SnapFulfill is one of the leading warehouse management technologies that empower companies across various industries, including B2C and B2B retail, third-party logistics, manufacturing, food and beverage, and electronics, to optimize their inventory, space, and resources. With SnapFulfill's class-leading warehouse management solutions, businesses can streamline operations and enhance efficiency. The software offers flexible deployment options and payment methods for diverse warehousing challenges. By utilizing SnapFulfill, industry experts gain access to advanced data warehouse tools that enable them to improve their supply chain business, enhance warehouse and distribution processes, and achieve optimal inventory management for increased productivity and profitability.

7. Indigo Software

Indigo WMS is an award-winning warehouse management system tool designed to enhance supply chain operations. It offers real-time control, visibility, and functionality for all warehouse processes. It is one of the best supply chain tools to track inventory in real-time, enabling efficient cycle counting, forward pick replenishment, and improved inventory forecasting. With Indigo WMS warehouse automation software, these tasks are automated, and the software ensures greater picking accuracy, reduces returns, and enables on-time and complete deliveries. It seamlessly integrates with existing systems, whether from SAP, Microsoft, Oracle, Infor, Sage, or other ERP, TMS, or SCP vendors, providing live and up-to-date data visibility across the entire supply chain process.

8. OrderWise

OrderWise is an order management system that empowers businesses in the consumer goods and retail sector to accelerate operations and deliver exceptional customer service. With its integrated features, OrderWise ensures seamless order processing and maximizes sales opportunities. By tracking orders from various sales channels, managing tight schedules, and making real-time adjustments, businesses can meet customer demands promptly. This is one of those supply chain management tools that provides valuable insights into customer purchase history and stock availability, enabling personalized recommendations and enhancing sales effectiveness. Whether for ecommerce, retail, or B2B sales, OrderWise streamlines order operations, making them smoother, faster, and more accurate.

9. Balloon One

Balloon One provides supply chain management tools, offering tailored software solutions to distribution, manufacturing, and e-commerce businesses. Its expertise lies in streamlining processes, optimizing resource allocation, and enhancing operational efficiency. With a focus on minimal disruption, Balloon One seamlessly implements software solutions, ensuring uninterrupted business operations. As an impartial advisor, the software offers both SAP Business One and NetSuite, thus allowing to recommend the ideal ERP system for each company's unique requirements. In addition, this software provides wholesale and distribution businesses with the robust HighJump WMS, a real-time warehouse management system that delivers scalability and flexibility.

10. Foxfire

Foxfire offers supply chain management tools specializing in Warehouse Management Systems (WMS). It offers WMS solutions, including features to optimize inventory, increase labor productivity, and enhance customer satisfaction. With over 20 years of industry experience, Foxfire has a proven track record of delivering measurable results to customers worldwide. This tool provides a comprehensive approach, including needs assessment, best practice recommendations, training, and ongoing support. Additionally, it is cost-effective by delivering low lifetime costs.

Conclusion

The warehouse automation market is experiencing significant growth, with a wide array of exceptional warehouse automation tools that offer high-quality solutions. Regardless of any special requirements, exploring the features of each warehouse automation tools is vital to identify the ideal fit for any business. Choosing the correct solution from the data warehouse tools list will help to improve inventory management and distribution efficiency through warehouse automation. Embrace the opportunity to streamline processes by leveraging supply chain management tools and warehouse automation solutions and experience the transformative power of automation to unlock the full potential of your business.

Read More

Warehousing and Distribution

Article | July 11, 2023

Even though there are distinct differences between demurrage, detention and port charges, many are still oblivious to these differences and there have been several questions on this blog relating to these charges.

This article is about how demurrage, detention, and port charges work.

International Trade and CostsWhen it comes to international trade, majority of the buyers and sellers use Incoterms to decide what each other’s responsibilities and liabilities are in terms of the business, especially related to costs.

Generally, there is very little room to manoeuvre in terms of additional and unbudgeted costs incurred on the shipment and therefore in their own interest it is important that the buyers and sellers take necessary precautions to ensure that all known costs relating to the business are discussed and finalised before the shipment commences.

There are many entities involved in the process of shipping a container from Point A to Point B, each with their own cost component, all of which have to be covered either by the seller or the buyer.

Demurrage, detention and port charges are just some of these costs that may be applicable in a shipment.

While some of the port charges are valid and unavoidable, demurrage, detention and some of the port charges (like port storage, early arrival, late arrival, amendment, shifting etc) are entirely avoidable if everyone in the chain follows the process that they need to follow.

What are port charges?

Port charges, as the name suggests are a set of charges levied by the port or terminal which the container passes through.In terms of container shipments, port charges may include but not limited to below :

Terminal Handling Charge (THC)

Is quite simply the charge levied by the port for the loading and discharging of a container from the ship.. THC differs from port to port, terminal to terminal around the world and is charged both by the load port and discharge port.If the cargo is transhipped anywhere along the route, then the transhipment port also charges this THC but that is paid by the shipping line directly to the port and this quantum is usually included in the ocean freight charged by the line.

Early Arrival Charge

A charge levied by some of the ports/terminals for a container that arrives in the terminal BEFORE the stacks into which it is to be taken has been opened.. Early arrival can happen due to various reasons like a container missed the stacks for the previous vessel narrowly, but since the container is packed, it needs to be taken to the port, The acceptance of containers prior to the stacks/gate open is at the discretion of the Port/Terminal Operator and on the circumstances surrounding the operation of the vessels.

Late Arrival Charge

A late arrival charge is a charge levied by the port for a container that arrives in the terminal AFTER the stacks into which it is to be taken has been closed.. This could be due to delays in documentation, packing delays, inspection, trucking delays and many other situations.The acceptance of containers after the closing of stacks/gate is at the discretion of the Port/Terminal Operator and on the circumstances surrounding the operation of the vessels and if the containers can be accepted without disrupting the schedule of the vessel and ports.

Stuffing/Destuffing of Containers

Some ports/terminals allow the stuffing (packing)/de-stuffing (unpacking) of the containers within the port area and charge customers based on the port tariff.This activity may happen at ports that provide CFS services and allow containers to be packed or unpacked in the port or due to some mistakes when the cargo was originally packed – say incompatible hazardous cargoes packed together.Depending on the port/terminal/country, the port charges may be charged directly to the customer (importer or exporter) or to the shipping line, who in turn will charge this to the customer.

Of course, this is not the full list of port charges but these charges have been mentioned as it relates to the subject under discussion,Demurrage and DetentionWhile some of these port charges may be unavoidable, demurrage and detention charges on the other hand are avoidable charges, but in a lot of cases due to mishandling, miscommunication, misunderstandings and not following the proper protocols, these charges occur..When they do occur, these charges may create quite a financial impact on the whole business and sometimes these costs could be so prohibitive that some customers abandon their cargoes at the destination due to these costs.

Although the most common market practice is to combine demurrage and detention, there are several cases where these are charged separately, and therefore it is important to know the difference between demurrage and detention.

Read More

Transportation

Article | April 26, 2023

Risk management has been a problem for as long as supply chains have existed. Because of the interdependence of all its connections, even a minor issue in one isolated region has the potential to jeopardize a whole global supply chain. As a result, when major global trends and events occur, the potential for widespread supply chain disruption is enormous.

Global supply chain risks and market disruptions have reached an all-time high. The most notable of them is the COVID-19 pandemic. In a 2020 survey, the Institute for Supply Management discovered that 95% of companies faced operational issues due to the pandemic. As a result, business executives all around the globe believe that if they want to be more resilient and competitive in the present market, they need to modernize and make significant changes to their supply chain strategy.

Other recent factors that have had a significant impact on traditional supply chain practices include the fast pace of change in consumer behaviors and a pretty unstable trade and political environment.

In the last ten years, e-commerce spending has tripled, and internet shopping had increased by 149% in 2020 compared to the previous year. With the growth of e-commerce, there has been a rise in customer demand for faster delivery and more personalized shopping experiences. The Amazon Effect refers to the growing expectation for same-day delivery and its effect on businesses and logistical networks. To be resilient enough to react to these rising demands, supply chain managers have had to make fast and significant modifications to their logistics and warehousing networks, as well as discover new ways to collaborate with third-party fulfillment partners.

Even before the impact of COVID-19, American businesses were attempting to reduce their dependence on foreign manufacturers and suppliers. Foreign tariffs and trade policies had become more unpredictable by 2019, and businesses were seeking technological solutions to make the supply chains more self-sufficient and resilient. As a result, integrating digital transformation and Industry 4.0 technology into supply chain operations is quickly becoming a top concern for global business leaders.

How does Supply Chain Resilience Work?

A flexible contingency plan and the ability to react swiftly to operational disruptions are important characteristics of effective supply chain management. However, to be truly resilient, a supply chain must be able to predict and anticipate disruptions and, in many cases, avoid them entirely.

Strategic supply chain planning is an important step in achieving resilience because it synchronizes all supply chain components and increases visibility and agility. Supply and demand needs are better understood, and production is synchronized due to supply chain planning. This integrated, forward-thinking approach assists businesses in better anticipating problems, reducing the impact of supply chain disruptions, and improving overall operations.

When a business has the digital systems to analyze and make sense of Big Data, it significantly improves supply chain resilience. Artificial intelligence-enabled systems can curate disparate data sets from across the business and the globe. To discover trends and opportunities, news, competitor activity, sales reports, and even customer feedback can be examined together. The system's connected devices are constantly monitored, providing real-time insights about where and how processes can be automated and improved. For instance, AI, machine learning, and modern databases acquire and handle Big Data and analyze and learn from it in an almost infinite number of ways. This enables intelligent automation across the network and provides supply chain managers with the real-time insights they require to respond quickly to disruption and unexpected events.

Supply chain managers have traditionally sought to limit the number of partners and suppliers in their network to minimize operational and logistical complexity. This approach is based on the stability of the social, environmental, and political systems. Unexpected disruptions in one region can slow or even stop network operations across the board. Supply chain resilience technologies, such as blockchain, sensors, and advanced analytics, enable supply chain managers to monitor complex partnerships and supplier contracts even in the most remote parts of their network.

Profitability in the supply chain has always been dependent on minimizing excess and keeping inventories as lean as possible. Capacity and inventory buffers are expensive, and supply chain managers have often bet against disruptions to keep prices low. When the pandemic struck, many businesses discovered the real cost of the gamble. Supply chain operations can involve on-demand manufacturing, virtual inventories, and predictive demand forecasting using digital supply chain technologies to remain resilient, even in times of unexpected disruption.

Benefits of a Resilient Supply Chain

Finding a successful balance between supply and demand is a significant issue for any supply chain manager in an increasingly competitive market. Many businesses that have cut costs on diversification, supply chain technology, and other resilience measures have lately discovered the true cost of those choices. However, when businesses engage in diversification, supply chain technologies, and other resilience measures, they can achieve a variety of business benefits, including:

More efficient operations: Better resilience often results in less risk and a greater capacity to invest in innovation and growth. For example, according to a 2020 global business analysis conducted by Bain and Company, businesses that prioritized their investment in supply chain resilience had up to 60% quicker product development cycles and were able to increase production capacity by up to 25%.

Enhanced productivity: Resilient supply chain solutions lead to the overall system increased productivity. According to a McKinsey 2020 survey, supply chain leaders from across the world report increased productivity due to resilient supply chain systems, and 93% of those surveyed plan to prioritize resilient supply chain strategies for investment in the next year.

Risk reduction: Supply chain activities are often the most vulnerable to risk and loss in many businesses. Supply chains, by nature, are geographically distributed and functionally complex. As a result, supply chains are particularly vulnerable to risk. Resilient supply chain technologies minimize risk by providing insight into all network operations and enabling companies to improve and adjust their processes and logistics in real-time.

Technologies for an Agile Supply Chain

Digital transformation and modern supply chain technology provide businesses with the resilience and competitive advantage they need to react swiftly to disruptions and opportunities.

Artificial intelligence (AI): AI-powered supply chain systems can offer deep procedural and operational insights by gathering and analyzing data from many sources. Predictive analytics and Big Data analysis can assist in predicting risk and demand and recommending measures and reactions in the company.

Machine learning: Machine learning enables the discovery of patterns in supply chain data and the identification of these influential factors - all while constantly learning. This enables supply chain managers to react fast with the finest workflows and operational strategies available.

Industrial Internet of Things (IIoT): The IIoT network in a supply chain comprises connected devices and objects with sensors and unique IDs that allow them to transmit and receive digital data. They collect information and communicate with the central system. AI can analyze and understand this data to enable quick decisions and intelligent automation of supply chain operations and procedures.

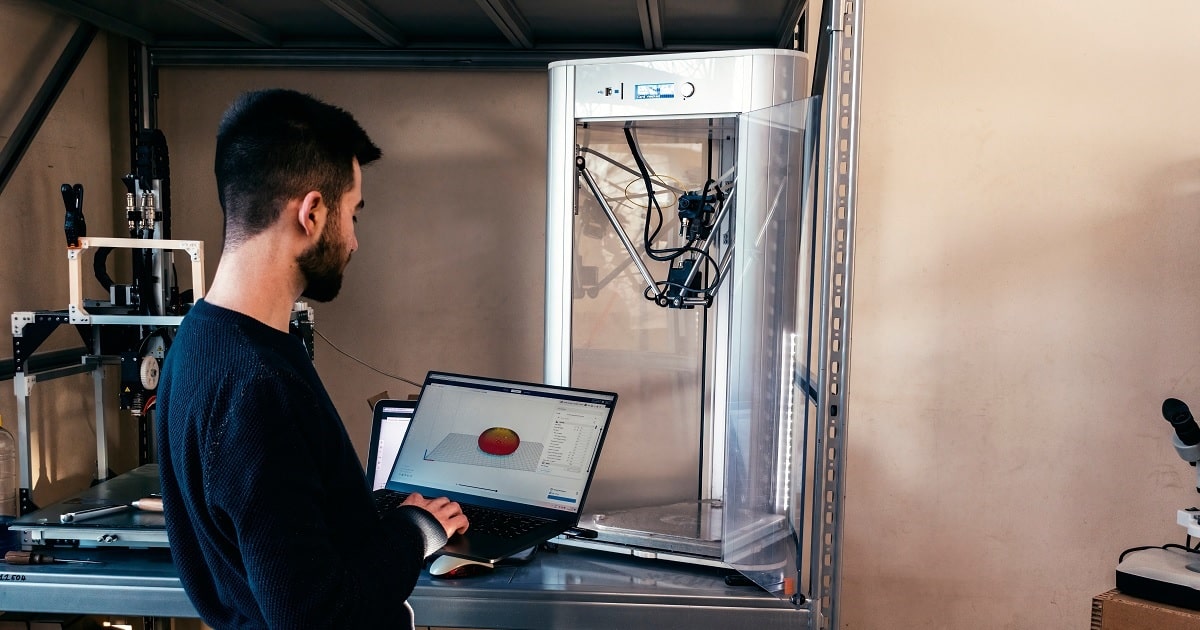

Additive (3D) printing: Smart factories can quickly reprogram 3D printers to produce specific products on-demand without disrupting regular business operations in the long run. The accessibility of potential virtual inventories enables supply chains to defend themselves against disruption.

Robots and autonomous things: Robots and drones, which are intelligently automated for speed, efficiency, and accuracy, can adapt their operations on the go to meet quickly changing requirements. They also reduce the risk of harm by eliminating overly repetitive or dangerous tasks from human workers.

Modern databases: The resilient supply chain solutions rely on Big Data, advanced analytics, and real-time insights from modern databases. Supply chain technology can be improved to operate faster and most resilient when equipped with a modern ERP system and an in-memory database.

Resilience means more than just surviving a disruption in operations. A fully resilient supply chain and businesses survive hardship and use it to innovate and improve their business. Building a resilient supply chain is very important in this modern era because disruptions like a pandemic, wars, climate change, etc., are occurring a lot these days. A resilient supply chain helps businesses to survive and thrive even during tough times. To read more about ways to boost supply chain performance, click here.

FAQ

What is supply chain resilience?

Supply chain resilience refers to the supply chain's capacity to be prepared for unexpected risk events, react and recover swiftly to potential disruptions, and grow by shifting to a new, more desirable state in order to improve customer service, market share, and financial performance.

How is supply chain resilience measured?

A supply chain's resilience index is calculated by aggregating its company's resilience index. Given that supply chain company's performance influences overall supply chain performance, supply chain resilience should be measured using the companies' resilience index.

{

"@context": "https://schema.org",

"@type": "FAQPage",

"mainEntity": [{

"@type": "Question",

"name": "What is supply chain resilience?",

"acceptedAnswer": {

"@type": "Answer",

"text": "Supply chain resilience refers to the supply chain's capacity to be prepared for unexpected risk events, react and recover swiftly to potential disruptions, and grow by shifting to a new, more desirable state in order to improve customer service, market share, and financial performance."

}

},{

"@type": "Question",

"name": "How is supply chain resilience measured?",

"acceptedAnswer": {

"@type": "Answer",

"text": "A supply chain's resilience index is calculated by aggregating its company's resilience index. Given that supply chain company's performance influences overall supply chain performance, supply chain resilience should be measured using the companies' resilience index."

}

}]

}

Read More

Software and Technology, Logistics

Article | July 8, 2022

Introduction

From warehouse robots to delivery drones, the supply chain is experiencing a tremendous upheaval. AI promises a totally autonomous and self-organized future supply chain. A fleet of vehicles utilizing a swarm algorithm can enhance cargo yard throughput; a trusted peer-to-peer ledger on blockchain architecture could change compliance in the sector; and wearables, mobile robotics, and machine learning technologies could speed up order fulfilment. IOT e-brokerage solutions can link shops to couriers and transporters with a click. Tomorrow's supply chain will be leaner, quicker, and self-organized. A few innovative technologies will fuel this unparalleled rate of change over the next 15 years. Here are the major technologies that are shaping the future of the logistics industry.

Logistics Technologies for the Future

Shipment Tracking Systems

Previously, customers ordered shipments, had an anticipated arrival date, and then were kept in the dark until they chose to call. Customers can now access shipping and tracking systems around-the-clock due to developments in the internet and software. This not only enhances the customer experience (cx), but it also saves the business time and money.

Internet of Things (IoT)

The IoT reduces costs and delays by minimizing hazards in the supply chain. Cabs, cargo ships, trains, etc., have sensors that link to an alarm system or dispatcher. These sensors analyze and communicate information to the crew, who learns about hidden threats. IoT isn't a new technology, but it continues to influence logistics by improving in-transit visibility and delivery.

Radio Frequency Identification (RFID)

RFID technology has been used for a few years to monitor inventories labor-efficiently. A product tag or sensor produces radio waves. The company processes the data. RFID tags are similar to barcodes, but their faster information transport and data processing appeal to companies and the direction of technology. Many organizations use RFID tags to track containers in warehouses.

Enhanced GPS Accuracy

Almost everyone utilizes GPS on their vehicles or smartphones. These devices' accuracy has improved over time, assisting lost drivers and enhancing the supply chain. By monitoring truck locations and boosting hauls with current traffic data, GPS increases efficiency and customer satisfaction.

Closing Lines

Unprecedented times have produced unprecedented transformations that will last for generations. Changing demographics, technology improvements, and COVID-19 impacts are altering global supply networks. We must understand the driving factors and act on what we learn to adapt and rise to the situation. For the sake of our current workforce and future generations.

Read More